Large Format Pellet 3d Printer FGF Industrial Granule Impresora 3d Printer

- DOWELL3D

- China

- 10-16 days

- 1000pcs/month

The DP-A Series Fused Granule Fabrication (FGF) pellet 3D printer uses thermoplastic pellets, which are less expensive than filament. Its low cost and high extrusion output make it suitable for producing large-scale models and prototypes.

-We are one of the largest 3D printer manufacturers in the global market.

-DOWELL3D has 11 years of production and export experience and has won praise from many satisfied customers.

-Provide various customized and personalized 3D printers.

-Provide high-quality and free after-service guarantee.

-Fast and convenient logistics services.

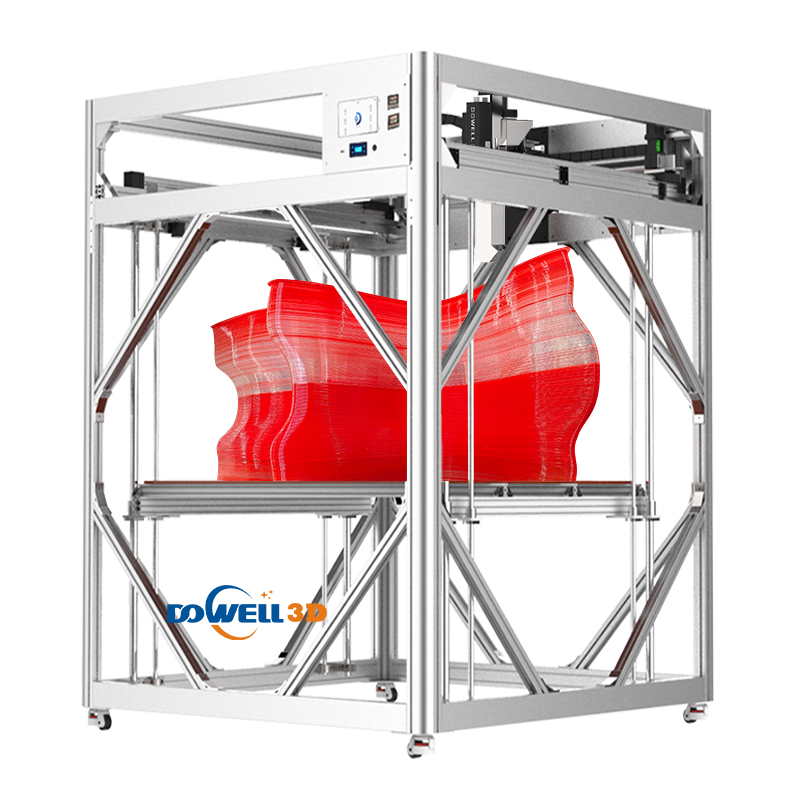

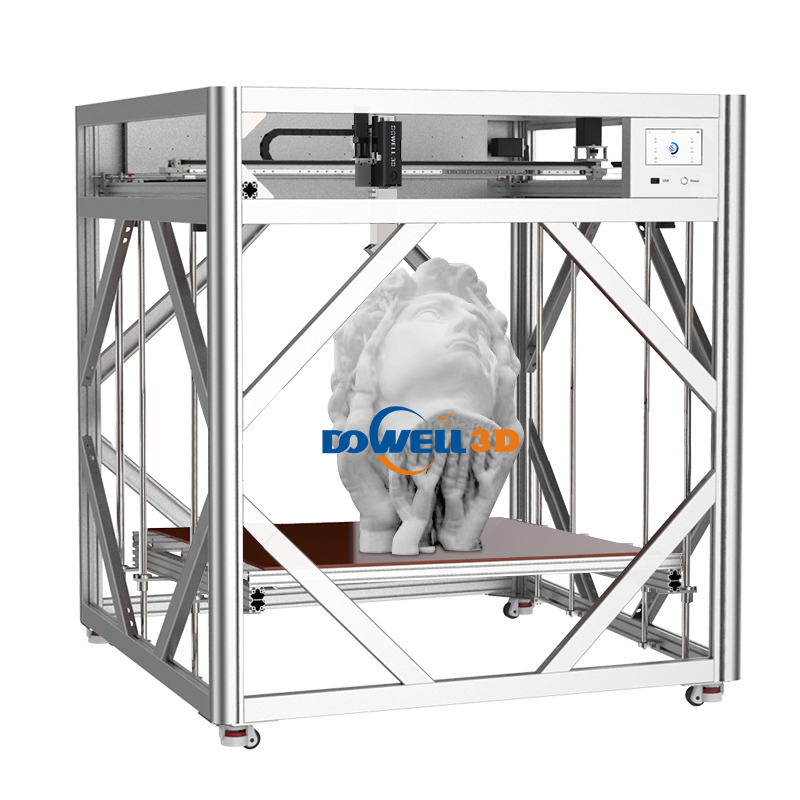

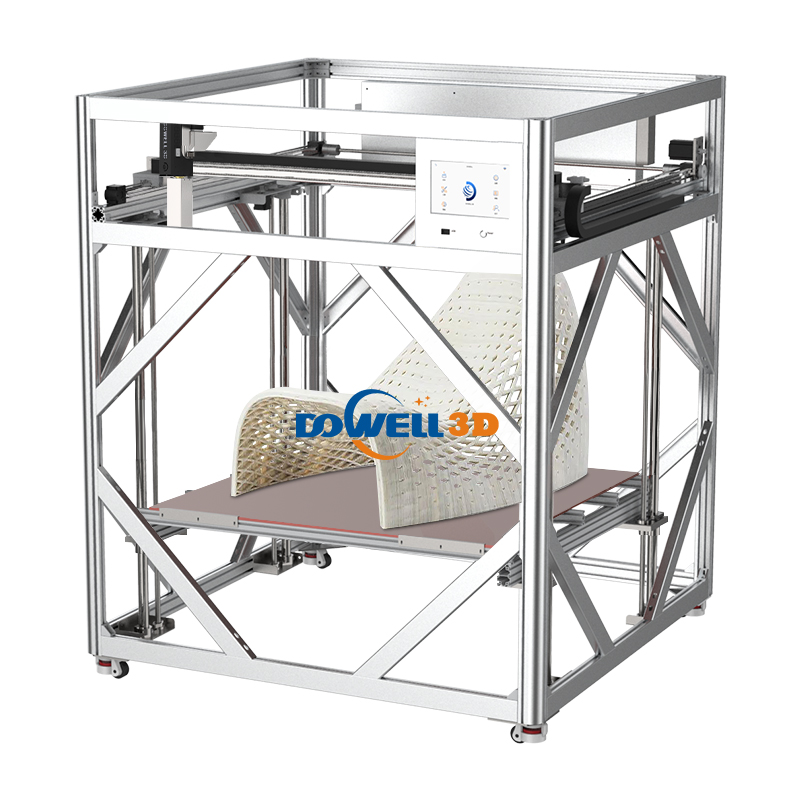

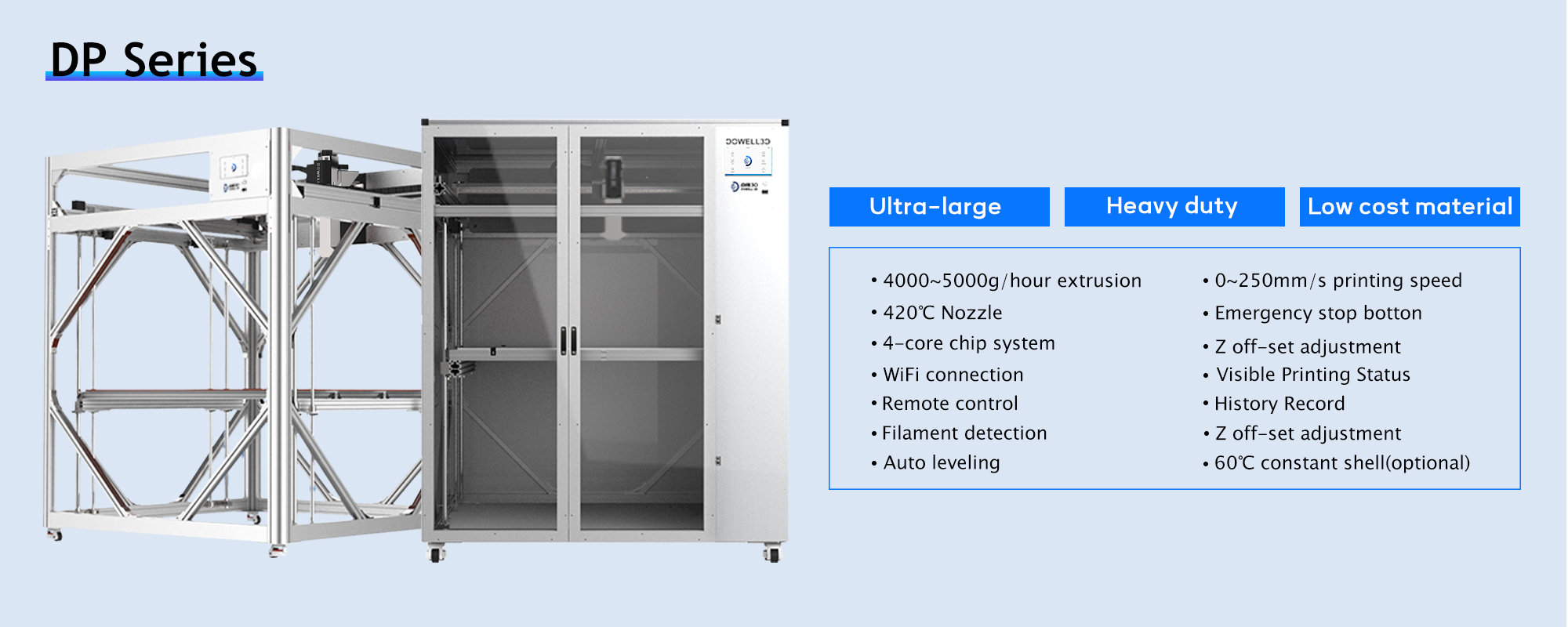

DP-A series pellet 3d printer

The Dowell pellet 3D printer is a large-format, high-speed thermoplastic extrusion printer.

Applications include functional prototypes, factory tooling, patterns and molds, car parts, sculptures, furniture

and end-use parts. With its large build volume, advanced features, and user-friendly interface, the DP-A 3d is

designed to take your 3D printing work to the next level.

Product parameters

| Printing | |

| Model Name | DP-A pellet 3d printer |

| Build Volume | From 1000*1000*1000 mm to 1600*2400*1600 mm |

| Print Technology | Fused Granular Fabrication(FGF) |

| Nozzle Diameter | 1.0/2.0/3.0 mm |

| Material | Pellet<Φ4mm recommended |

| Extruder | 3 Stage Screw extrusion, automatic feeding system |

| Technical Specifications | |

| Max extrusion flow rate | 4000-5000g/hour |

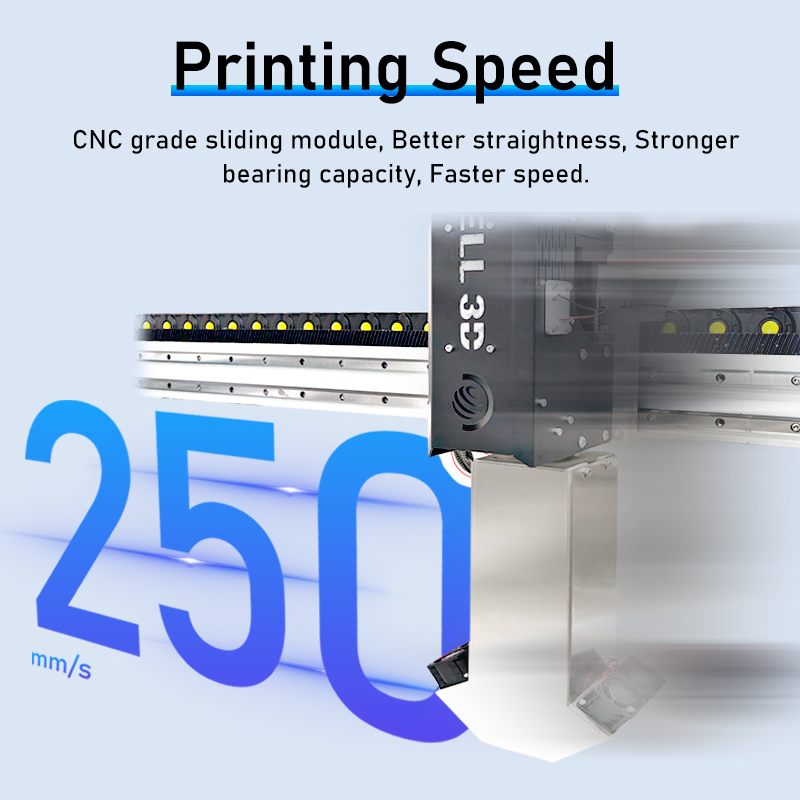

| Printing speed | 0-300mm/s |

| Nozzle temperature | 0-420 ℃ |

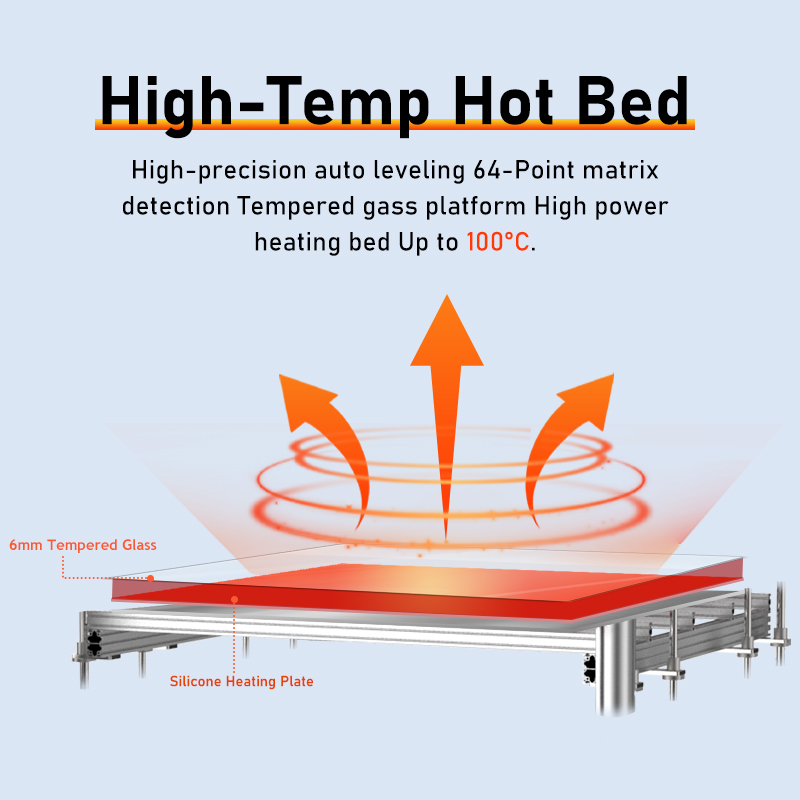

| Bed temperature | 6mm tempered glass 0-100 ℃ |

| Hardware&Software and Functionality | |

| Input power | 110/220V |

| File format | STL/OBJ/GCODE/JPG |

| Connection | SD Card / U Disk / WiFi |

| Operation firmware | Independent research and development |

| Transmission | Screw drive & Servo Motor |

| Operation interface | 10''full color touch screen |

| Feature Functionality | *Auto leveling *Remote control *Automatic feeding *3-Stage Temperature Control *Wifi connection *Visible Printing status *Visible temperature graph *Installable external camera *Configuration editable *Z-offset adjustment *Speed & extrusion & cooling adjustment *Gcode viewer *History record *Emergency stop button |

| Customization options | *60°c enclosure *Printing size |

Key Features & Advantages

Pellet-based Extrusion: Using thermoplastic pellets, which are less expensive than filament, significantly

reduces material costs.

High Deposition Rate: Pellet extruders deposit material much faster than filament extruders, typically up to

10 times faster, with a maximum extrusion rate of 5,000 g/h, increasing production speeds.

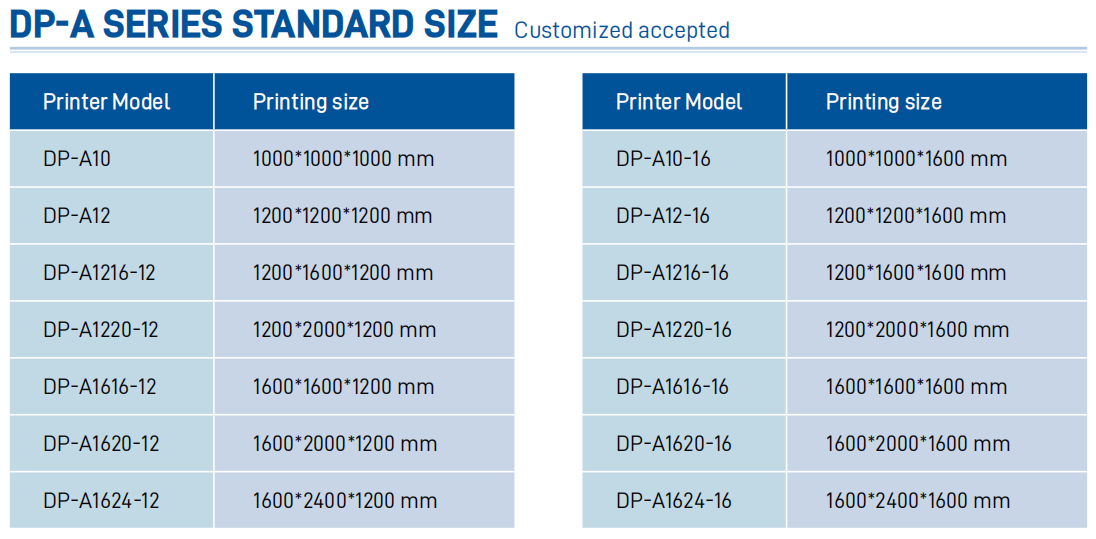

Large Build Volumes: These machines are designed for large-scale production, with build volumes that can

reach over 1 meter in all dimensions, (build sizes range from 1,000 x 1,000 x 1,000 to 1,600 x 2,400 x 1,600 mm),

allowing for single-piece large parts.

Cost-Efficient Production: The combination of lower material costs and high-speed printing makes them

a cost-effective solution for large-scale production.

Multiple Applications: They can be used in industrial applications, including the manufacture of molds,

patterns, fixtures, and large prototypes and end-use parts.

High Flow Screw Extrusion

The Dowell DP-A 3D printer uses an advanced screw extrusion system with a strong and uniform extrusion force,

which can achieve fine details and uniform adhesion at the same time, and the maximum extrusion speed can

reach 5000 grams per hour.

A three-stage temperature control system ensures smooth extrusion, and a water cooling system enables

high-speed, precise model printing.

420℃ High Temp Nozzle

High-temperature nozzles up to 420°C have a larger heating area and can quickly melt a variety of thermoplastic

pellets, supporting a variety of materials such as PLA, PETG, ABS, and TPE. Easily create durable, complex parts.

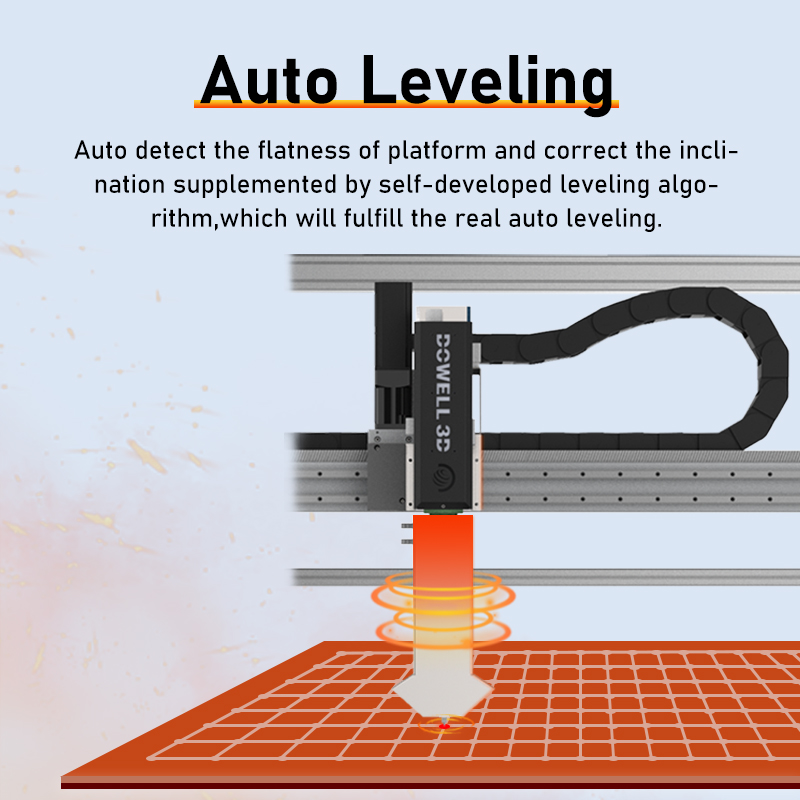

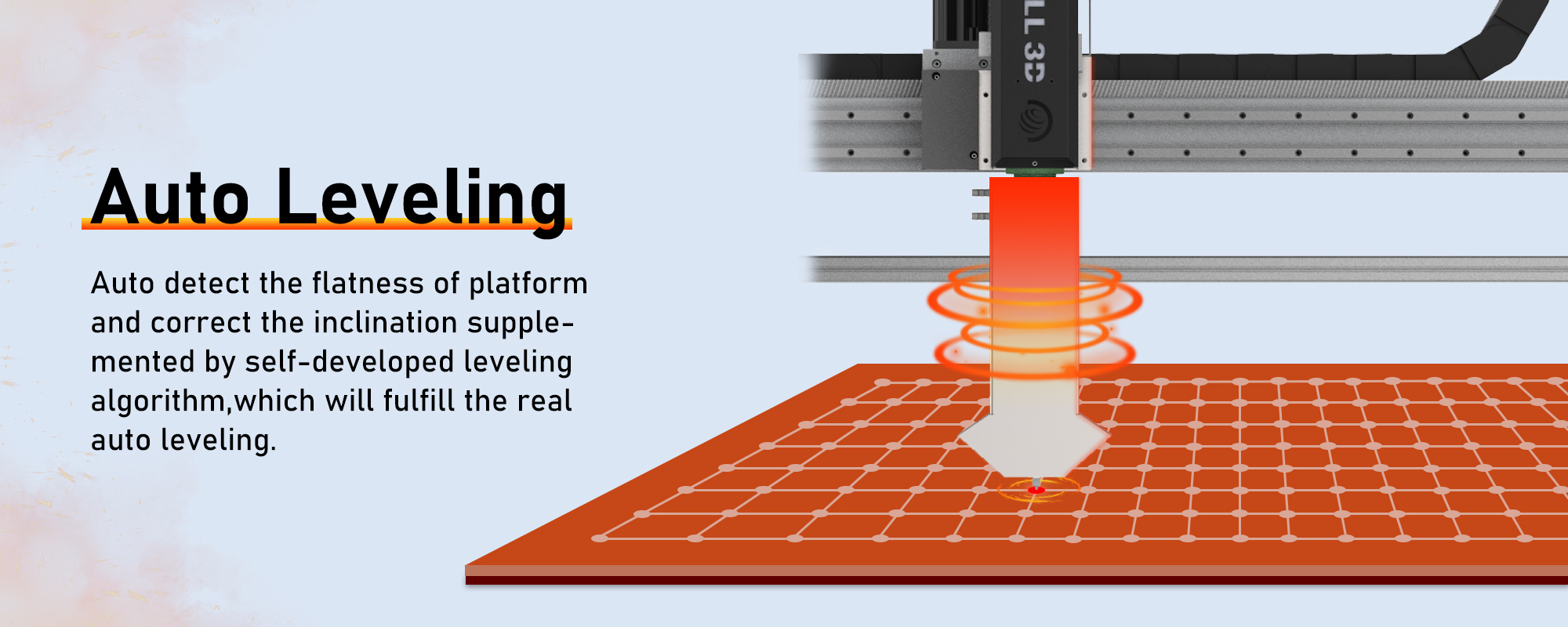

Auto Leveling

The DP-A Pellet 3D printer is equipped with an automatic leveling system based on high-precision sensors.

It automatically detects the flatness of the platform and corrects the tilt.

This system is supplemented by a self-developed leveling algorithm and 100-point matrix detection to achieve

true automatic leveling.

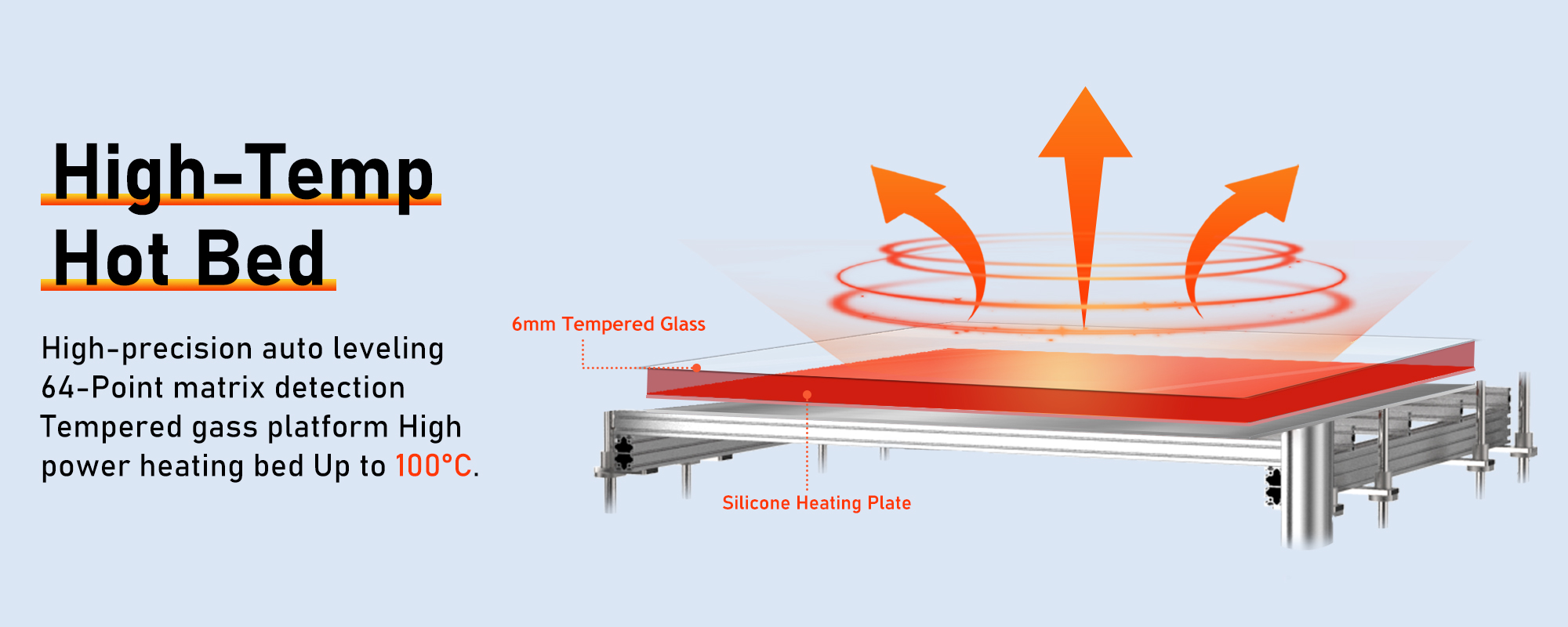

100℃ High Temp Hot Bed

*Silicone Heating Plate + 6mm Tempered Glass Platform

*High-power heated bed, anti-deformation

*Strong bearing capacity, the model is easy to disassemble

*Up to 100℃

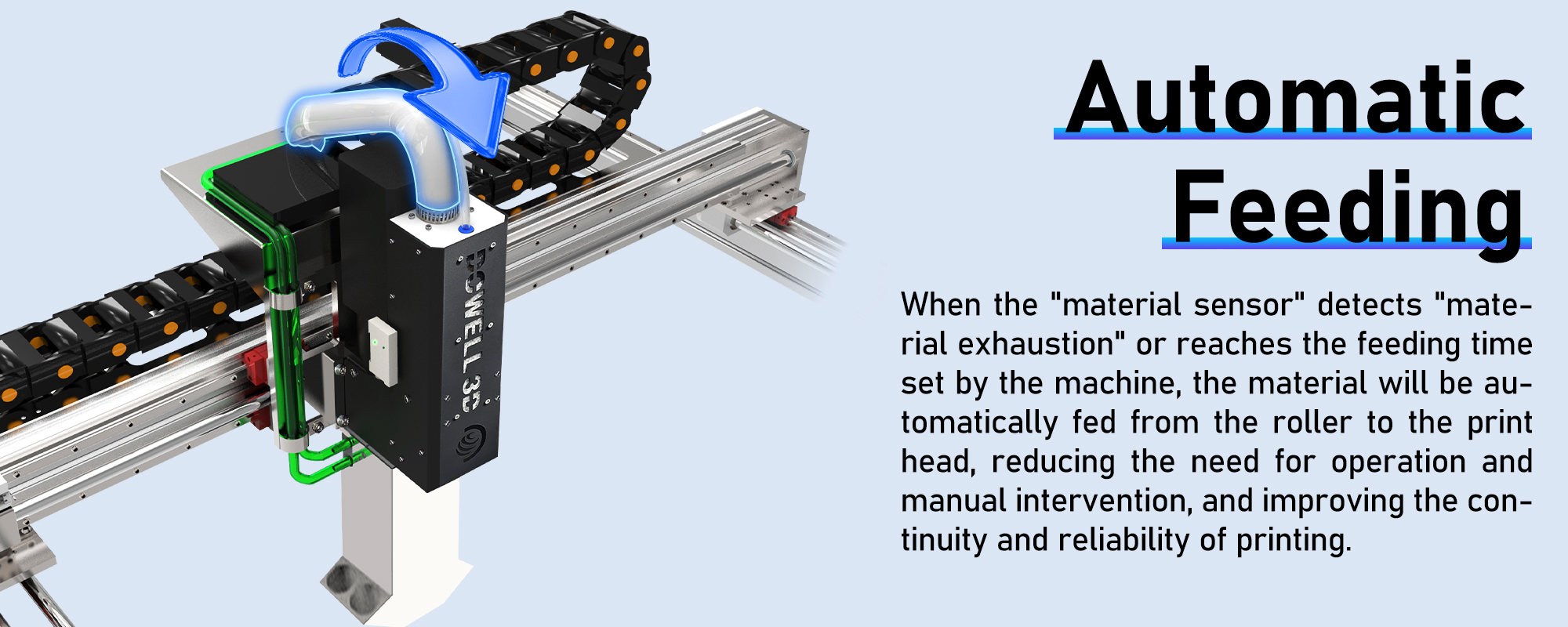

Automatic feeding

When the "material sensor" detects "material exhaustion" or reaches the feeding time set by the machine,

the material will be automatically fed from the roller to the print head, reducing the need for operation and

manual intervention, and improving the continuity and reliability of printing.

Water-Cooled System

This heat dissipation solution is designed for high-power printing, accurately controlling the temperature of

key parts to prevent problems such as blockage caused by overheating, ensuring printing accuracy and stability.

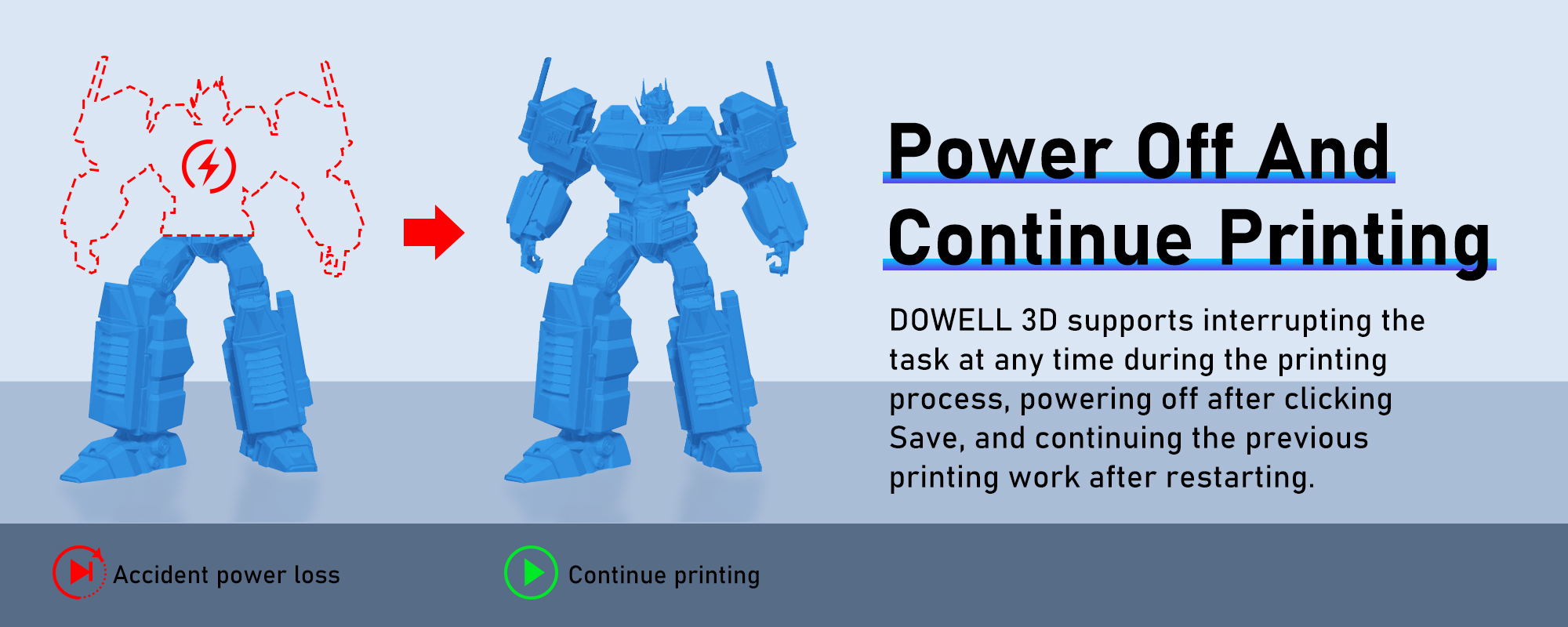

Anti-collision & Auto resume from power off

*The nozzle has a self-developed, inner part that has an anti-collision structure, which can effectively avoid

nozzle collision caused by wrong operation.

*Power failure protection, continue printing after recovery.

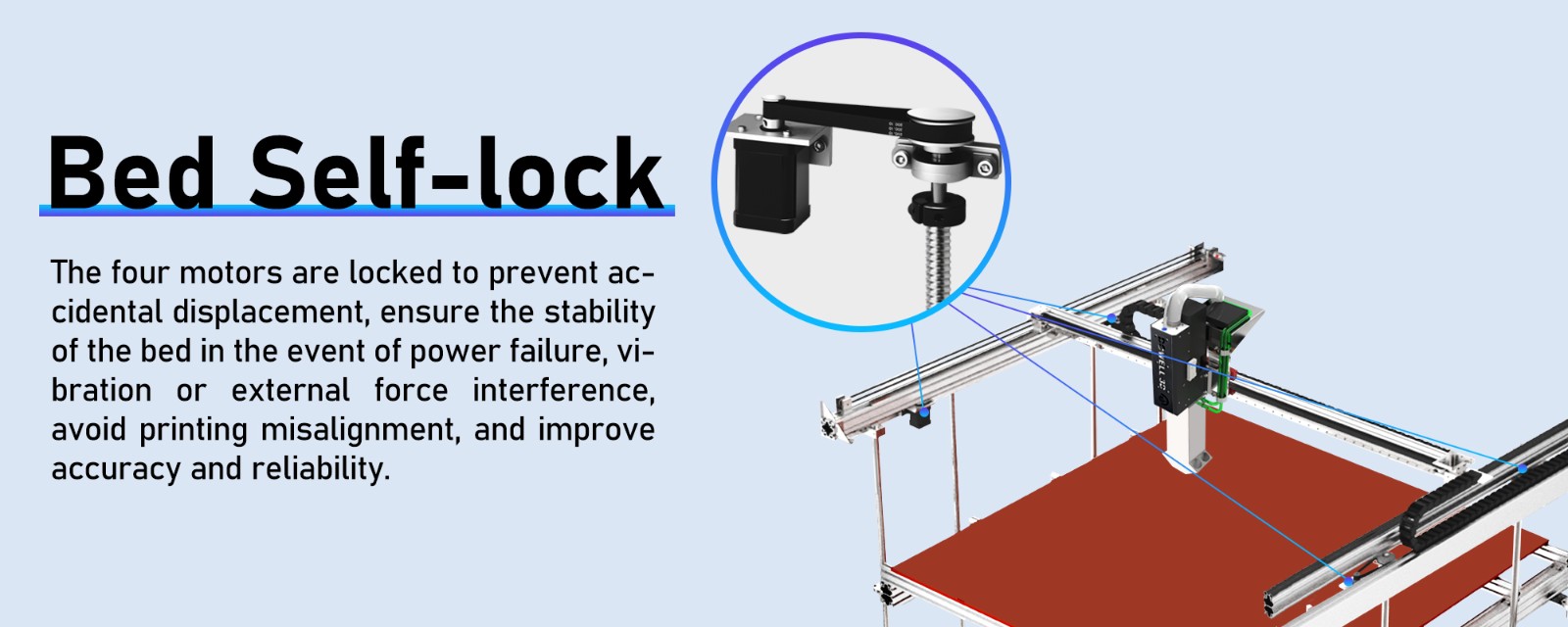

Four self-locking motors prevent accidental movement, ensuring bed stability in the event of power outages,

vibration, or external interference, preventing misalignment and improving accuracy and reliability.

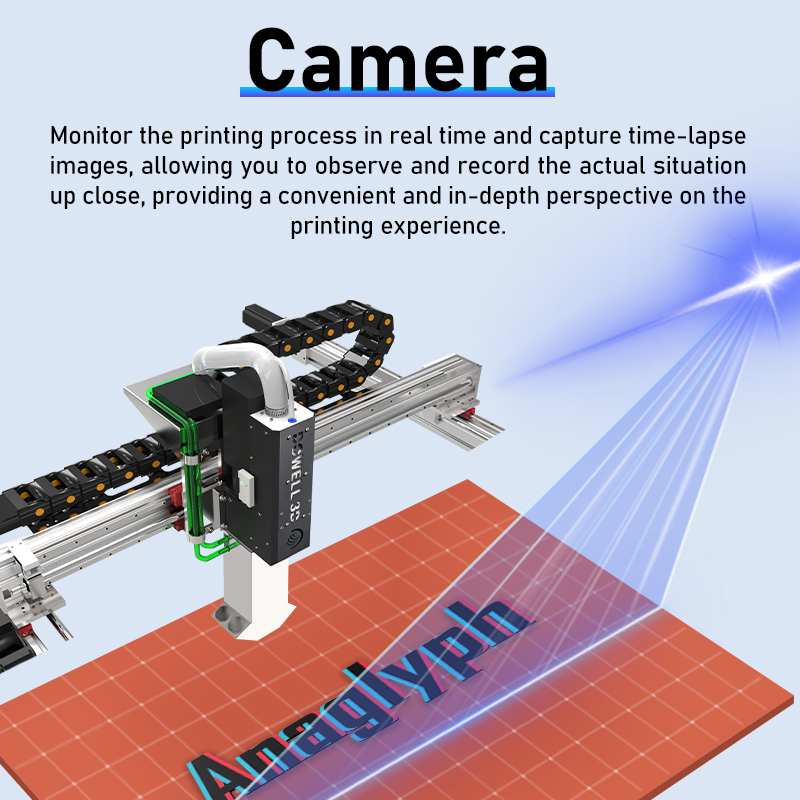

WiFi connectivity and remote control

Remotely connect to your printer, print files directly, and monitor the printing status in real time, making printing

easier and more convenient.

Technicians can also remotely connect to your printer for system updates and maintenance. Make printing easy.

We have the above 14 standard printer sizes.

If you need other sizes, please contact us for customization.

Customization options

Constant temp Enclosure

Custom Sizes

Promises:

*One-year warranty

*Factory direct sales

*Quality assurance

*Technical support

Official Notice:

Dear Valued Customers,

This is the only official store of Luoyang Dowell 3D Electronic Technology Co., Ltd.

We are the sole manufacturer and exporter of Dowell3D 3D printers and related products.

Please note:

We have not authorized any third-party websites or suppliers to distribute or resell our products.

Products sold under the "Dowell3D" brand on other platforms or websites are counterfeit and unauthorized.

They lack genuine quality, technical support, and after-sales service. Please exercise caution and discretion

when purchasing.

Choose us without hesitation; it will be the best decision you make.

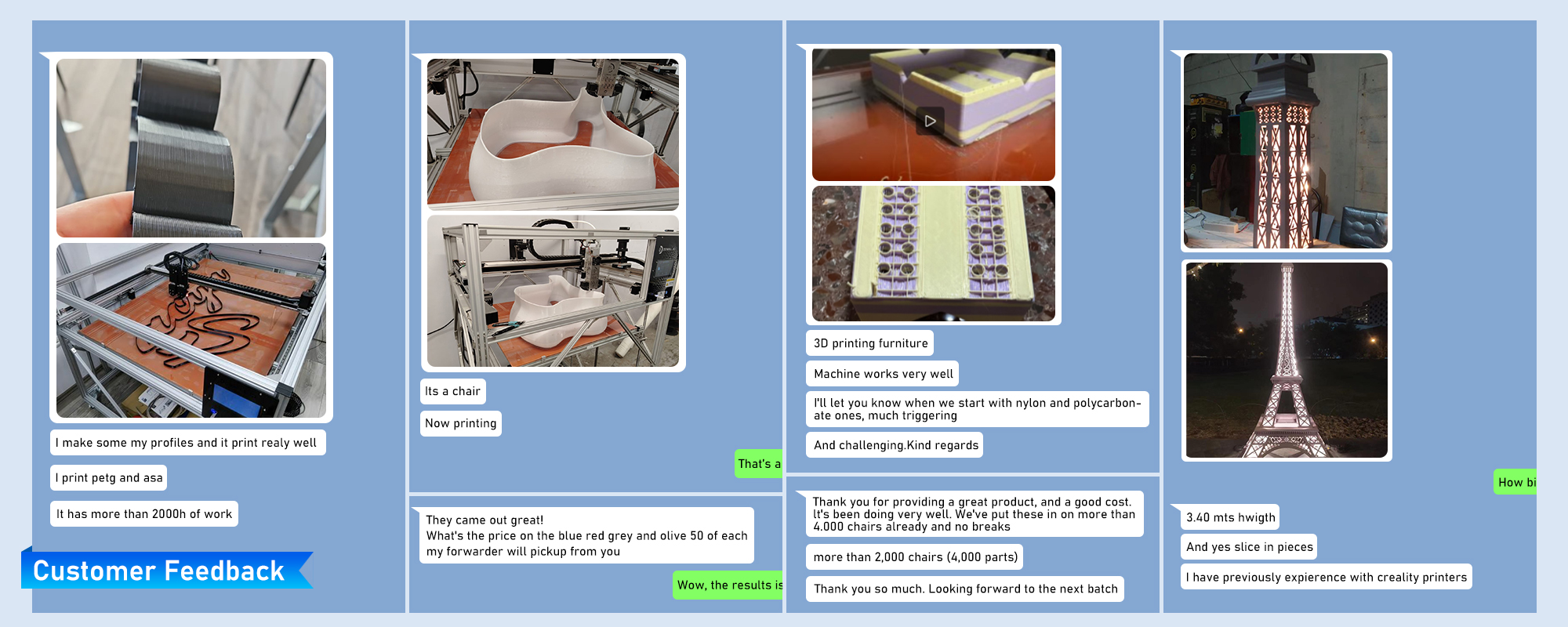

Application areas and customer feedback

FAQ

1. Are you a trading company or a manufacturer?

We are a 3D printer manufacturer with more than 11 years of R&D experience.

2. What certifications do you have?

CE, FCC, ROHS, etc.

3: Do you accept OEM/ODM orders?

Of course, we have our own R&D team to support the customization of the motherboard design and machine

design, testing, and production.

4. What services do we provide?

Delivery terms accepted: EXW, FOB, CFR, CIF, DDP, DDU

Shipping methods accepted: Sea freight, Air freight, DHL. FedEx, UPS

Accepted payment currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY

5. Is there a warranty for overseas customers?

Yes, the machine comes with a one-year warranty. We have professional technical engineers and instructional videos. The machine is fully automatic and easy to operate.