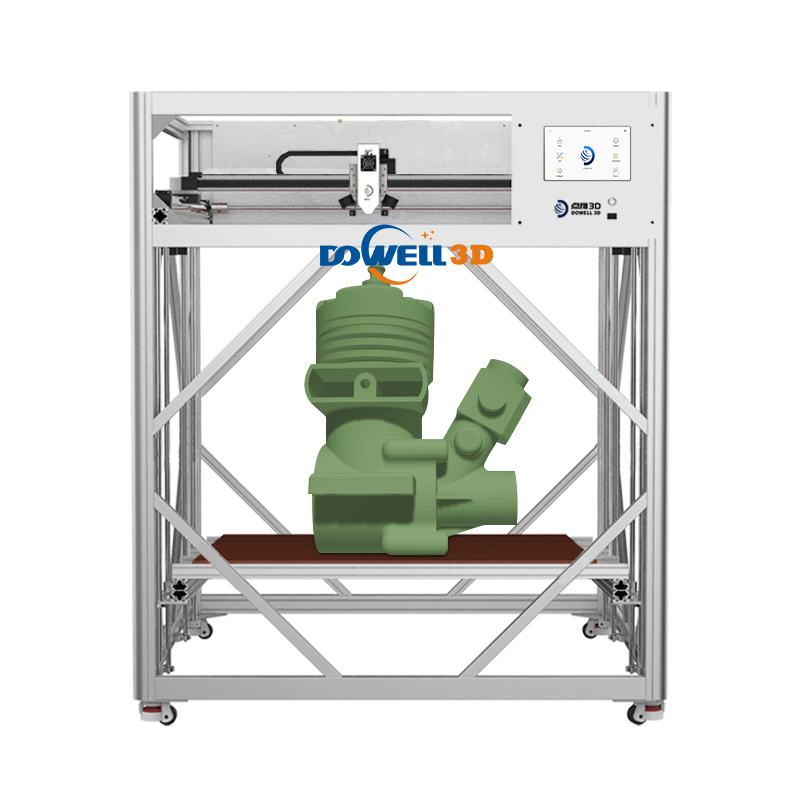

Industrial 3d Printer 1000×1000×1000mm Large Format 3d Printer Auto Leveling Digital 3d Printing Machine

- DOWELL3D

- China

- 10-16 days

- 1000 sets/month

The Dowell DL10 3D printer offers a large printing size of 1000*1000*1000mm and features a high-temperature nozzle (420℃) and bed (up to 100℃), ensuring compatibility with advanced materials like ABS, Nylon, and Carbon Fiber. It includes auto-leveling, Wi-Fi remote management, and a proximal feeder, enabling high extrusion flow rates of up to 1000g/hour.

DL SERIES 3D PRINTER

Product Overview:

The Dowell3D DL series is an advanced 3D printer designed specifically for industrial environments.

It combines an ultra-large build volume, an astonishing 1000 g/h extrusion rate, a heavy-duty reinforced

frame, and comprehensive intelligent management to meet the extreme demands for large size, high

throughput, and production-level reliability in fields such as engineering, automotive, sculpture, and

furniture manufacturing.

| Model | DL 10 3D Printer |

| Printer size | 1000×1000×1000mm |

| Frame | Thickened 80mm Aluminum Section |

| Nozzle diameter | 0.8/1.2/1.6 mm |

| Nozzle temperature | 0-420℃ |

| Bed temperature | 0-100℃ (Customized 150℃) |

| Positional accuracy | 0.02mm |

| Layer height accuracy | 0.04-0.6mm |

| Extrusion flow rate | Max 1000g/hour |

| Printing speed | 250-500mm/s |

| Operation firmware | Independent research and development |

| Operation interface | 10''full color touch screen |

| File format | STL/OBJ/GCODE/JPG |

| Filament available | 2.85mm PLA, PETG, ABS, ASA, WOOD, PLA+, PP, CARBON FIBER, GLASS FIBER, etc |

| Connection | SD Card / U Disk / WiFi / Camera |

| Input power | 110/220V |

| Basic functions | *Auto leveling *Filament sensor *Remote control *Wi-Fi connection *Visible Printing status *Visible temperature graph *Installable external camera *Configuration editable *Z-offset adjustment *History record *Speed & extrusion & cooling adjustment *Gcode viewer *Emergency stop button |

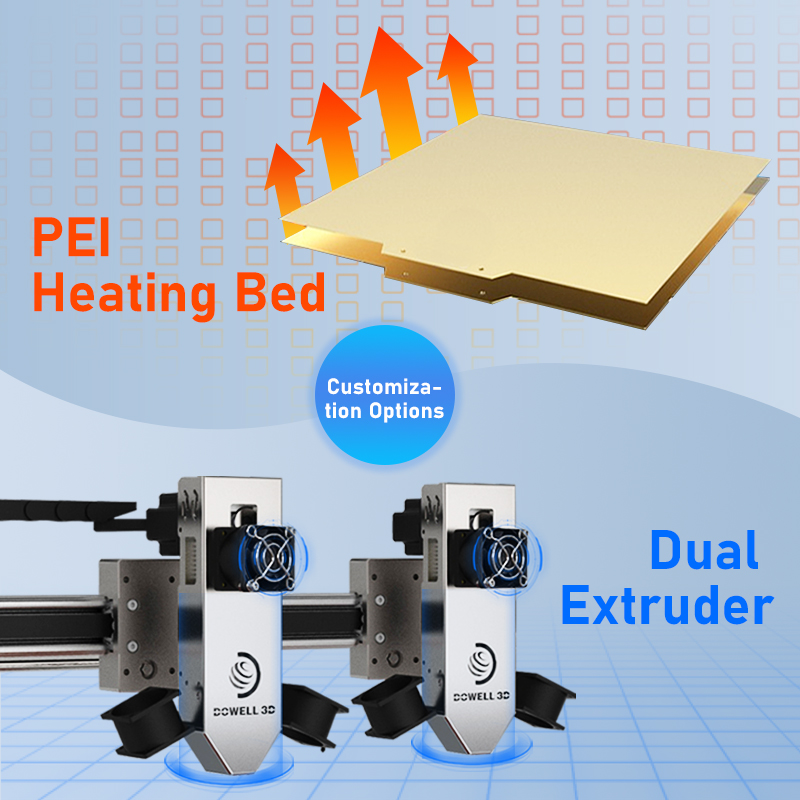

| Optional | * Dual extruder * PEI bed * 60℃ Enclosure * 150°c Heating bed |

Contact us today to request a custom quote for the DL Series!

80mm Thick Heavy-Duty Aluminum Frame

The DL Series utilizes high-quality aluminum extrusions

with a thickness of up to 80mm to create its entire frame.

This superior structure provides unparalleled rigidity and

stability for ultra-high-speed and ultra-large-scale printing,

ensuring sharp details and precise dimensions even at the

largest print sizes.

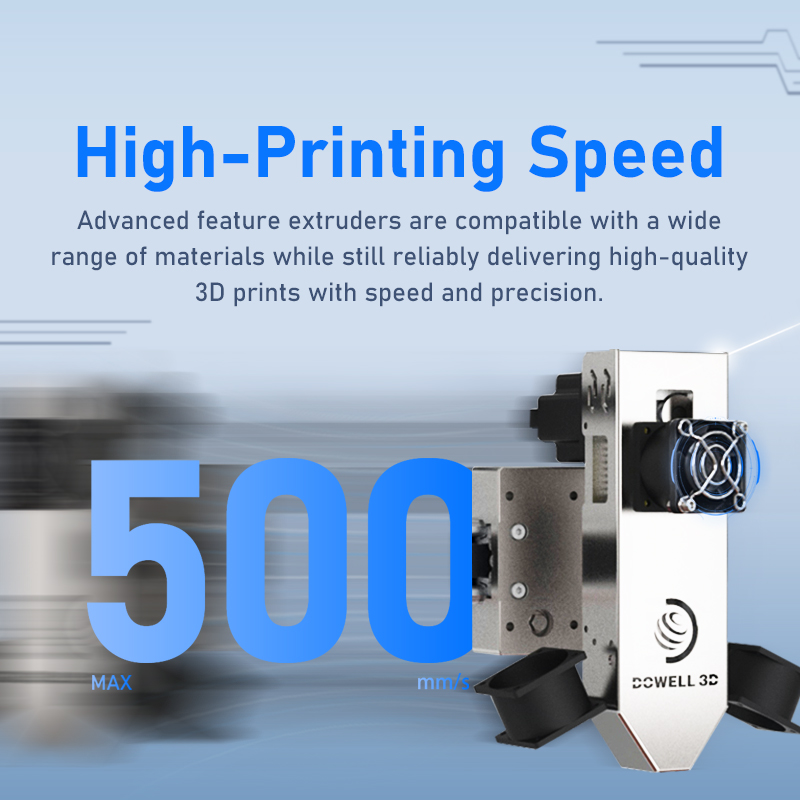

500mm/s high printing speed

The DL series supports high-speed printing of 500 mm/s, several times faster than traditional printers

while maintaining model accuracy. It reliably delivers high-quality, fast, and precise 3D printed models.

1000 g/h high extrusion flow rate

The Dowell DL series 3D printers utilize a powerful extrusion system. A 1000g/hour extrusion output

means more parts can be produced per unit time, significantly reducing the printing time of large models.

420℃ high-temp nozzle

The DL series 3D printers have a nozzle temperature of up to 420°C, which can quickly and fully melt a

variety of filaments such as PLA, PETG, ABS, ASA, WOOD, Glass fiber, Nylon, PP, PMMA, PVA, TPU, and

CARBON FIBER..., making it easy to create durable and complex parts.

Provides a variety of nozzle diameters (0.8/1.2/1.6 mm) to meet the needs of high-efficiency and high-flow printing.

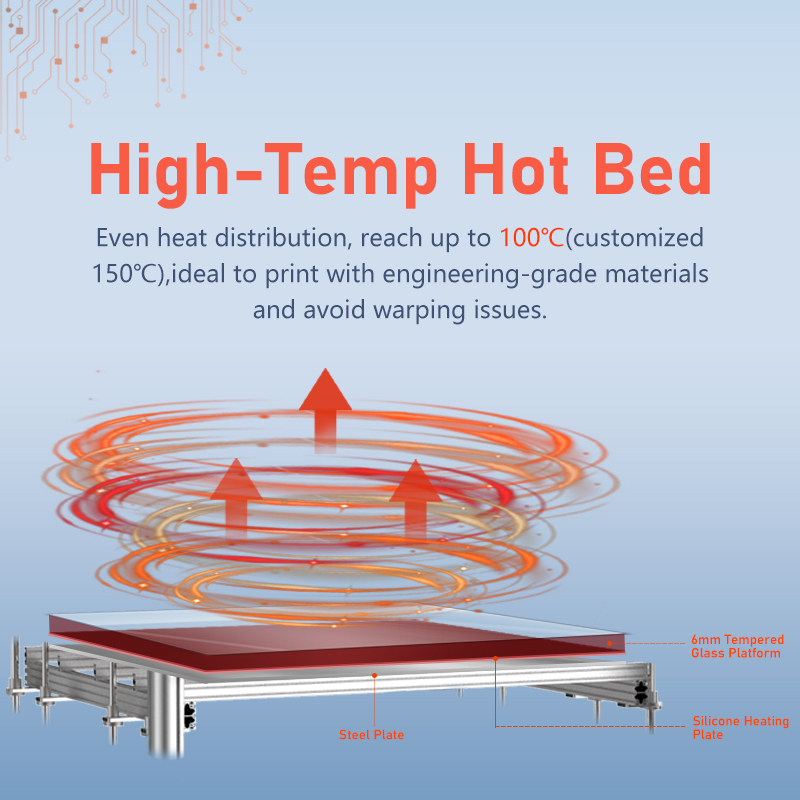

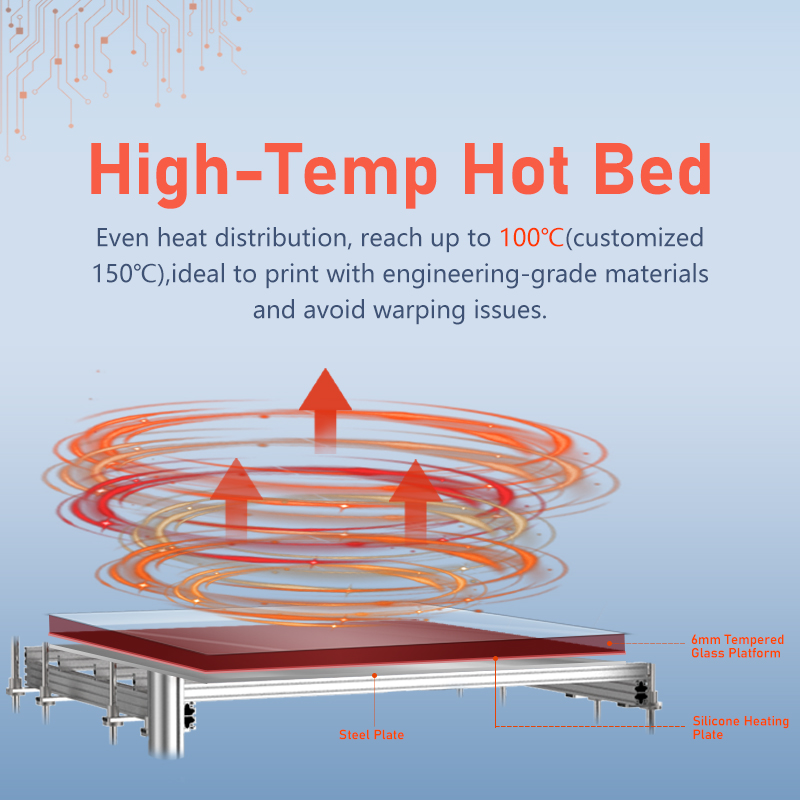

100℃ high temperature hot bed

Platform composition: Silicone heating plate + 6mm tempered glass.

High-power heated bed, uniform heating up to 100°C. The thickened tempered glass resists deformation,

maintains excellent flatness, and offers strong load-bearing capacity, making model disassembly easy.

Automatic Leveling System

The DL series is equipped with a one-touch leveling system that automatically detects platform flatness

and corrects tilt. This system, coupled with a proprietary leveling algorithm, achieves true automatic

leveling, ensuring a perfect first-layer print every time.

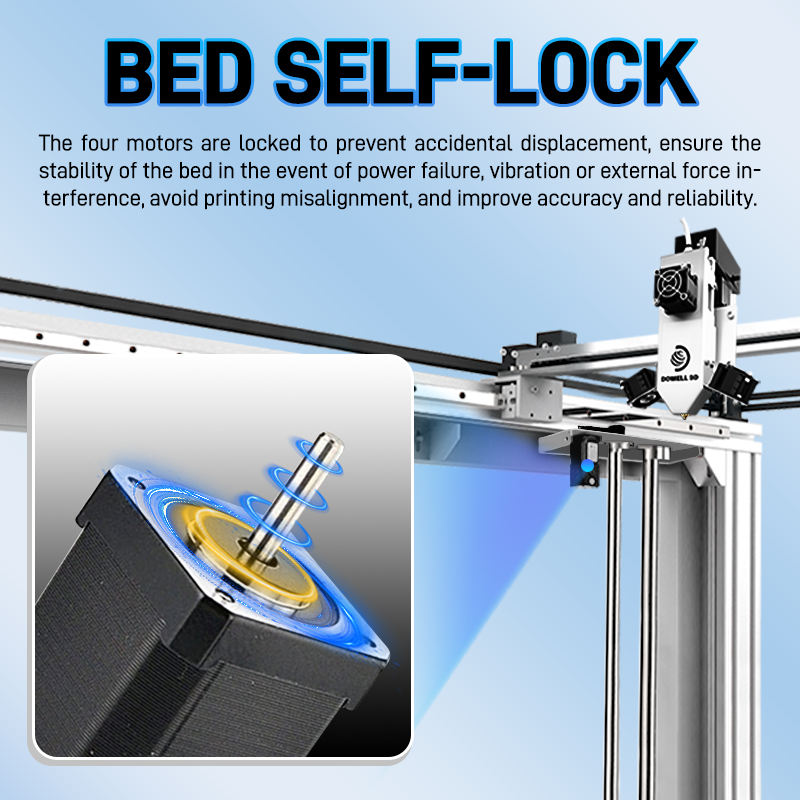

Automatic hot bed lock function

The hot bed automatically locks after printing is complete, ensuring the stability of the bed in the event

of power failure, vibration, or external force interference, avoid printing misalignment, and improve

accuracy and reliability, ensuring the safety of your prints.

10"full color touch screen, available in 15 languages

The 3D printer control interface, equipped with a large-size, full-color, multi-language touch screen, can

significantly enhance the user experience and lower the learning threshold. It is especially suitable for

novice users and facilitates global users to operate in different language environments, improving work

efficiency and convenience.

REMOTE CONTROL

Supports remote monitoring of printing progress, adjustment of parameters and receipt of abnormal

alarms via WiFi or the cloud, realizing cross-platform operation and effectively improving production

management efficiency.

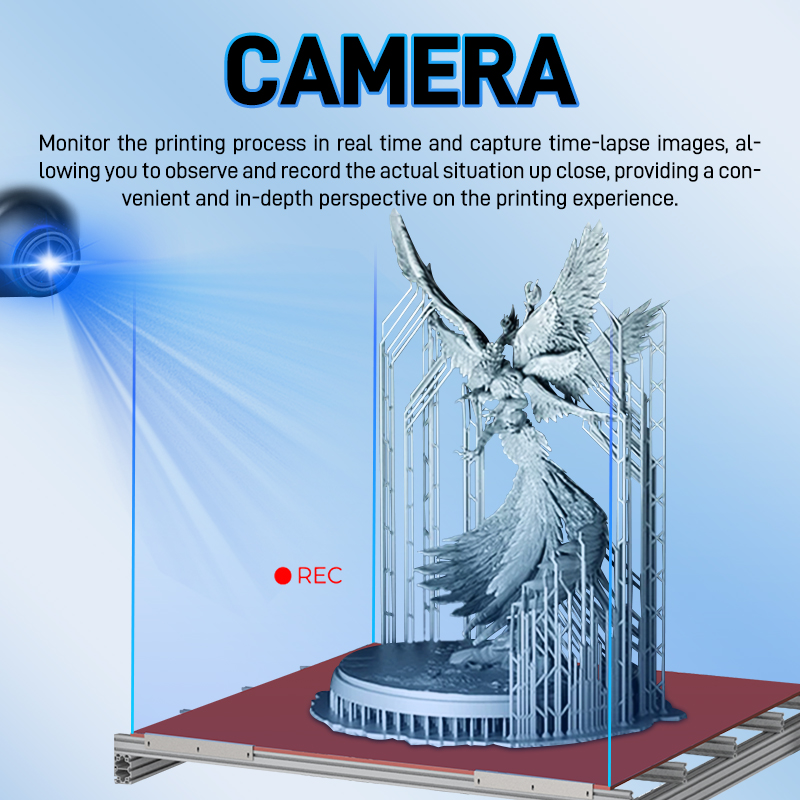

Built-in camera

Monitor the printing process in real time and capture time-lapse images, allowing you to observe and

record the actual situation up close, providing a convenient and in-depth perspective on the printing experience.

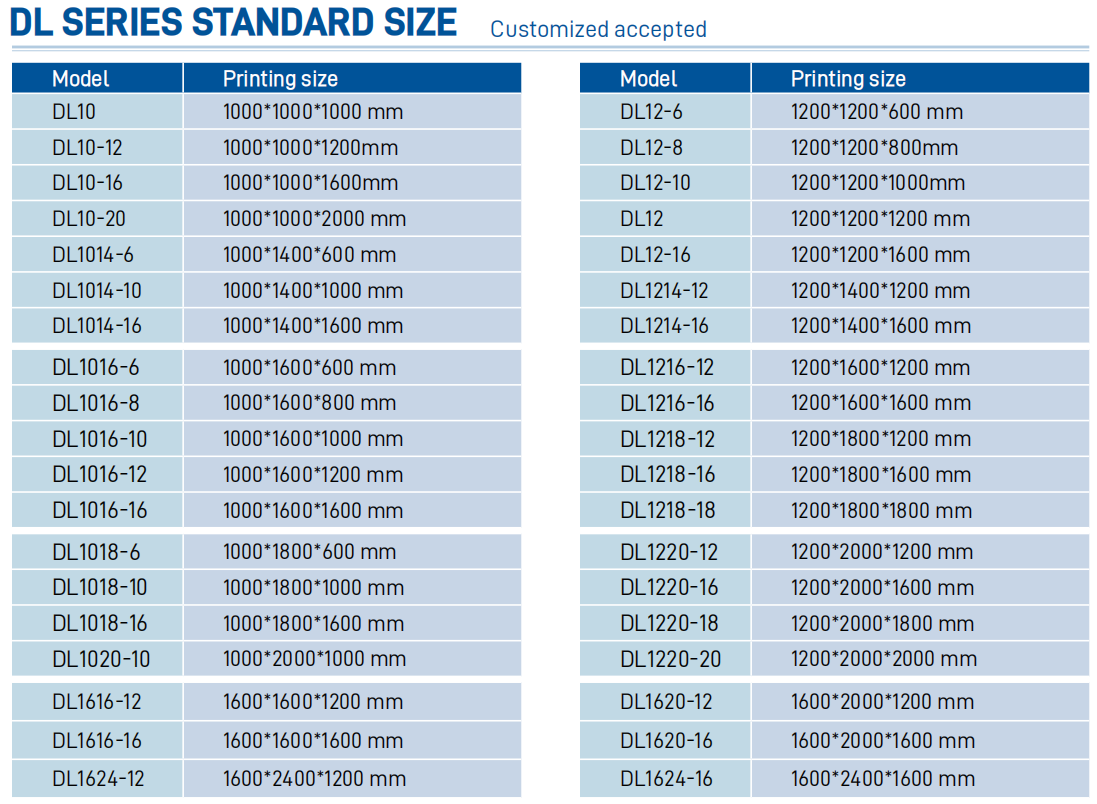

Extensive Printer Size Options

To meet more specialized application requirements, the DL series offers the following professional

options to further enhance its capabilities:

1. Custom sizes and housings:

We can customize the printing size according to your needs, and the 60℃ enclosed constant temperature

shell effectively prevents high shrinkage filaments from shrinking and warping during printing.

2. Custom Dual Extruder Heads:

Dual extruder heads allow the printer to use two different filaments or colors simultaneously, enabling

the printing of complex color models or supporting structures to reduce print time.

3. Custom PEI heated bed:

It provides excellent print surface adhesion, withstands high printing temperatures, and resists wear.

It ensures the first layer of your print adheres firmly to the heated bed, reducing warping and improving

print success rates.

Official Notice:

Dear Valued Customers,

This is the only official store of Luoyang Dowell 3D Electronic Technology Co., Ltd.

We are the sole manufacturer and exporter of Dowell3D 3D printers and related products.

Please note:

We have not authorized any third-party websites or suppliers to distribute or resell our products.

Products sold under the "Dowell3D" brand on other platforms or websites are counterfeit and unauthorized.

They lack genuine quality, technical support, and after-sales service. Please exercise caution and discretion

when purchasing.

Choose us without hesitation; it will be the best decision you make.

Customer Printing Case

Dowell Company Profile

1. Luoyang Dowell Electronic Technology Co., Ltd., established on December 31, 2014, is one of the

largest 3D printer manufacturers in the global market, specializing in high-quality, environmentally

friendly 3D printing consumables and large-format industrial-grade 3D printers.

2. Dowell offers a wide range of specialized printers, including sculpture printers, automotive printers,

pellet printers, and furniture printers. These printers are widely used in industries such as automotive,

aerospace, biomedical, advertising signage, mold manufacturing, furniture design, and sculpture production.

3. Services We Provide:

1) Highly Competitive Pricing

2) Recommendations for the most suitable and appropriate products based on our project experience

3) Excellent technical team and comprehensive after-sales service

4) Smooth communication

5) Efficient OEM and ODM services

FAQ

1. Are you a trading company or a manufacturer?

We are DOWELL, a 3D printer manufacturer with over 11 years of R&D experience.

2. What certifications do you have?

CE, FCC, ROHS, etc.

3. What payment method is available for you?

T/T (Bank transfer), PayPal, Western Union, Credit card, WeChat Pay, Ali Pay, T/T

4. Could you send products to my country?

Yes, we do business in every corner of the world. Please contact us to consult the details delivery charge.

5. How do you guarantee the quality of the printer?

We conduct 100% testing before shipment. We provide test photos and videos before shipment.

We guarantee that our 3D printers will be free of any quality issues before shipment. Once confirmed,

we will arrange shipment.

6. How about the after-service?

Our printers have a 1-year warranty. And if you have any printing problems, our after-sales team will

respond quickly to solve your problem by video or online service.