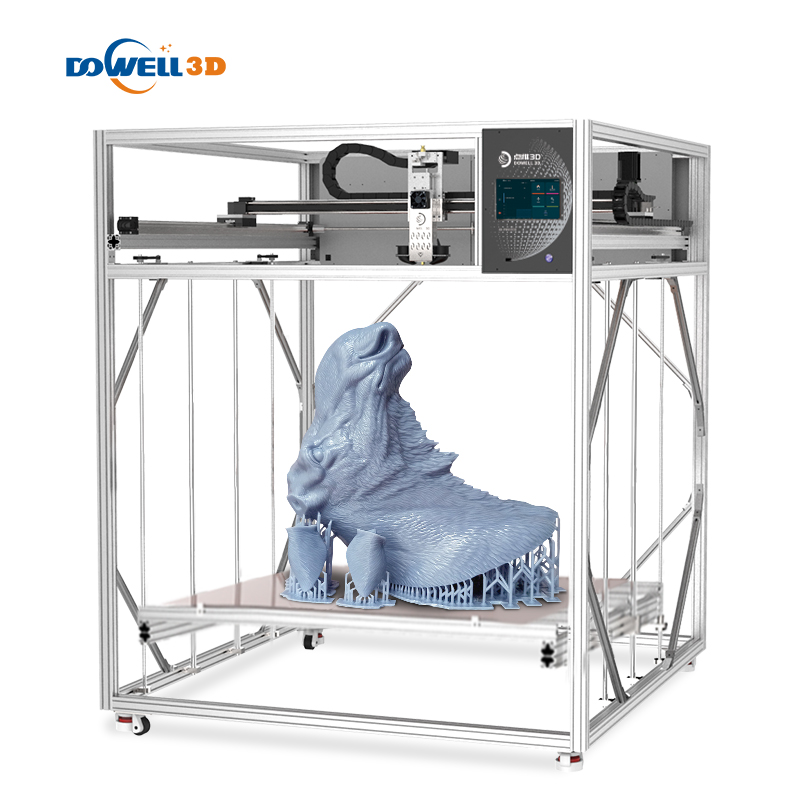

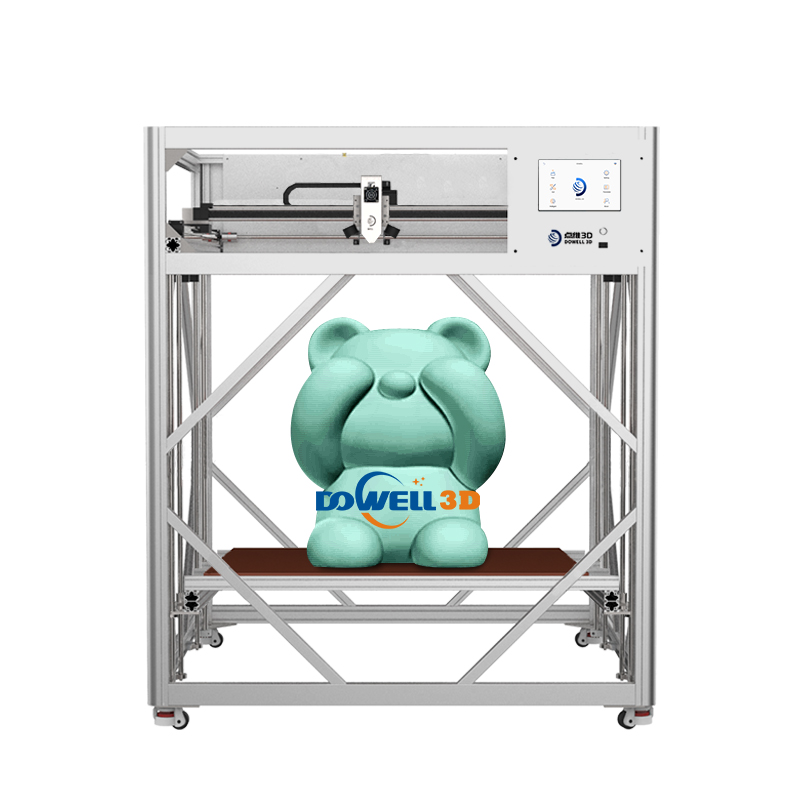

FDM Industrial 3D Printers 1600mm Large High Speed Precision for Automotive Rapid Prototyping house 3d printer 3d printing machine

- DOWELL3D

- China

- 10-16 days

- 1000pcs/month

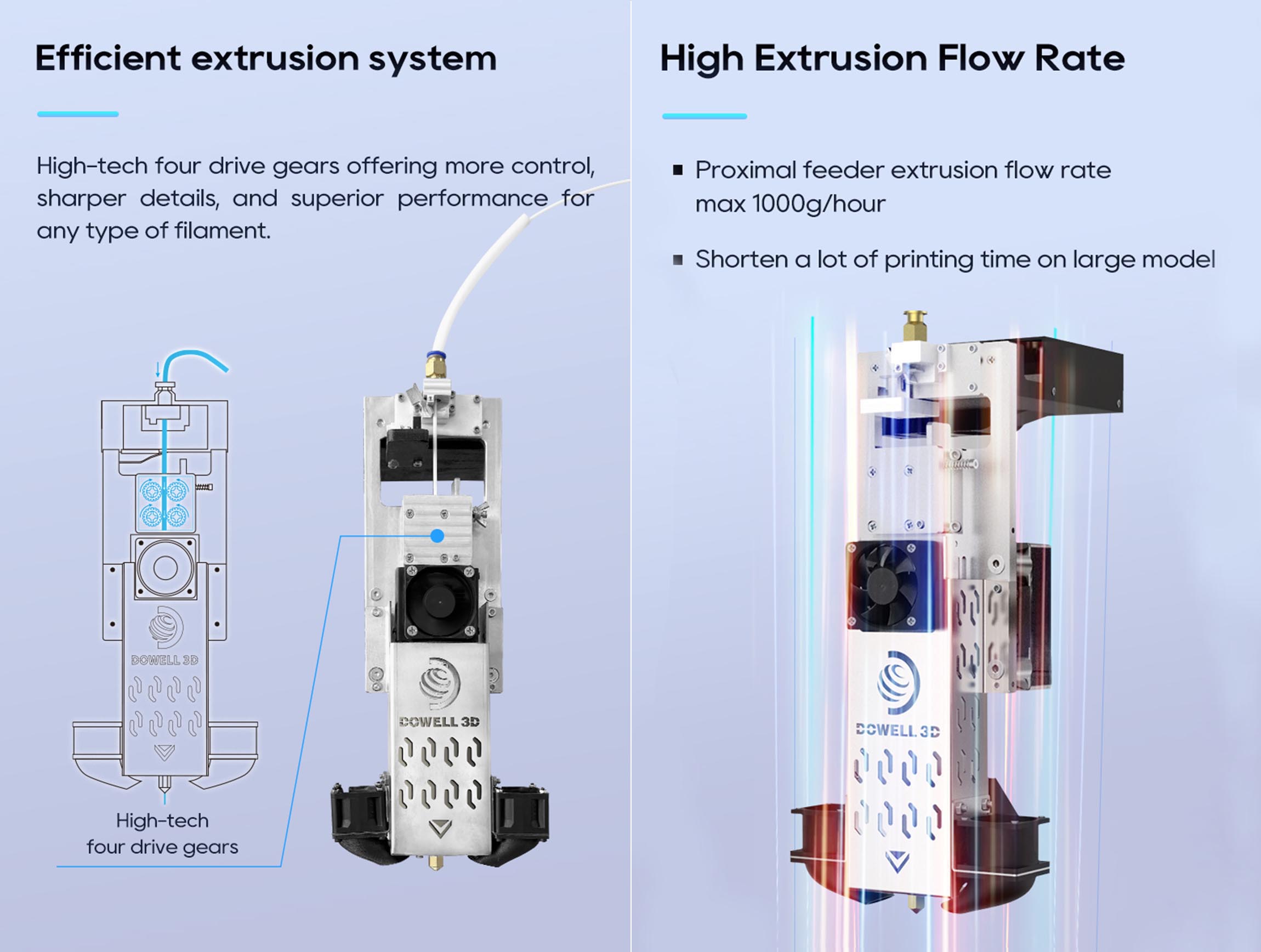

Efficient Extrusion System & High Extrusion Flow Rate:

*High-tech four drive gears offering more control, sharper details, and superior performance for any type of filament.

*Proximal feeder extrusion flow rate max 1000g/hour, Shortens a lot of printing time on large models.

FDM Industrial 3D Printers Large High Speed Precision for Automotive Rapid Prototyping house 3d printer

Specification of DOWELL3D DM-Pro Series Printer

| Product | DOWELL3D DM1216-12 Pro High Speed 3D printer | |||

| Printing Size | 1200*1600*1200mm | |||

| Frame | 60mm aluminum section | |||

| Printing Bed | 6mm tempered glass | |||

| Nozzle Diameter | 0.8/1.2/1.6mm | |||

| Nozzle Temperature | 0-420℃ | |||

| Bed Temperature | 0-100℃ | |||

| Location Accuracy | 0.02mm | |||

| Layer Height Accuracy | 0.04-0.6mm | |||

| Extrusion Flow Rate | Max 1000g/hour | |||

| Printing Speed | 250-500mm/s | |||

| Operation Firmware | Independent research and development | |||

| Operation Interface | 10''full color touch screen | |||

| File Format | STL/OBJ/GCODE/JPG | |||

| Filament Available | 2.85mm PLA, PETG, ASA, ABS, PVA, TPU, WOOD, CF, etc. | |||

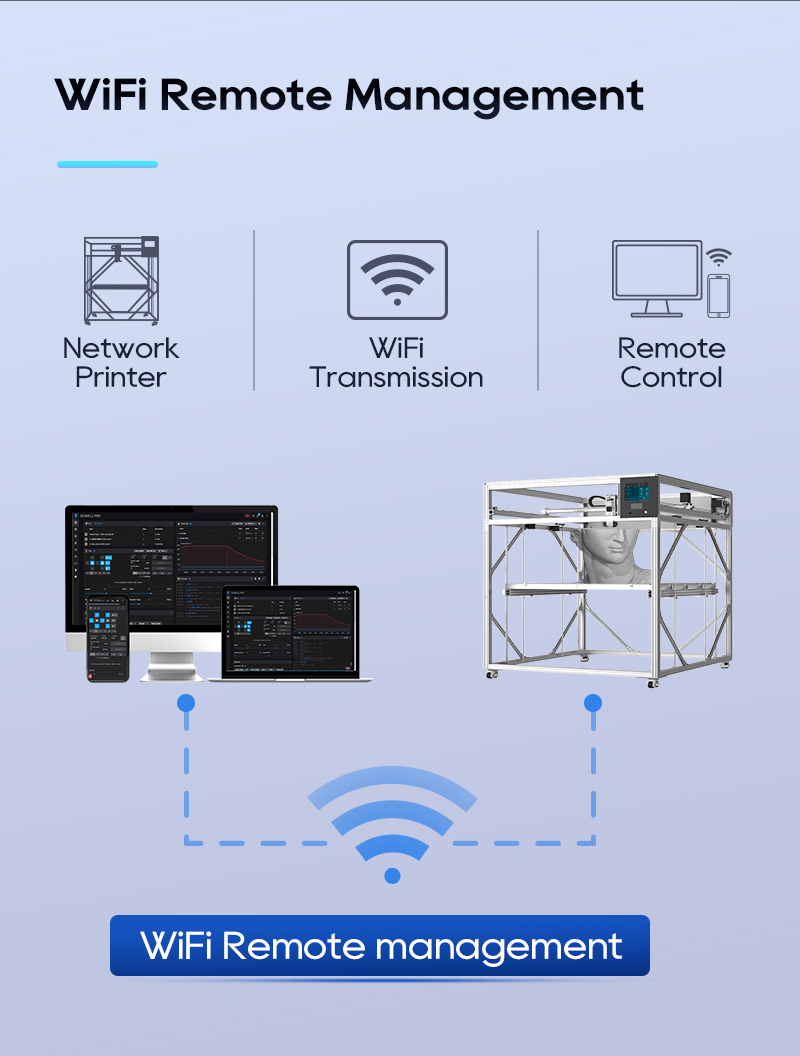

| Connection | SD Card/U Disk/WI-FI | |||

| Input Power | 110/220V | |||

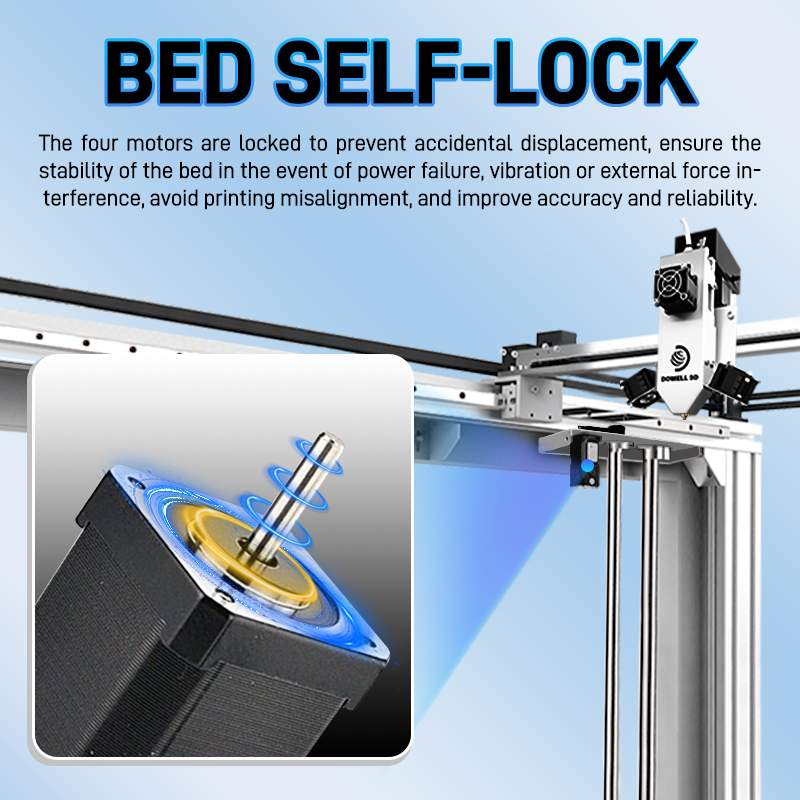

| Basic Functions | *Camera *Bed self-lock *Z-offset adjustment *Filament sensor *Visible Printing status *Gcode viewer *Remote control *Visible temperature graph *History Record *Wifi Connection *Configuration editable *Emergency stop button *Auto leveling *Speed & extrusion & cooling adjustment *Nozzle anti-collision *Power off and continue printing | |||

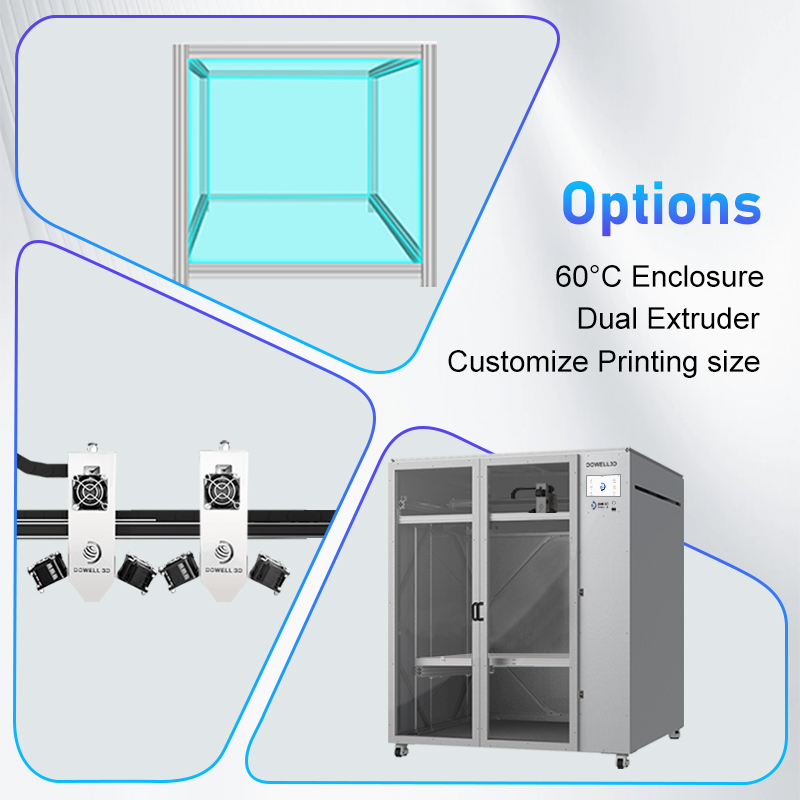

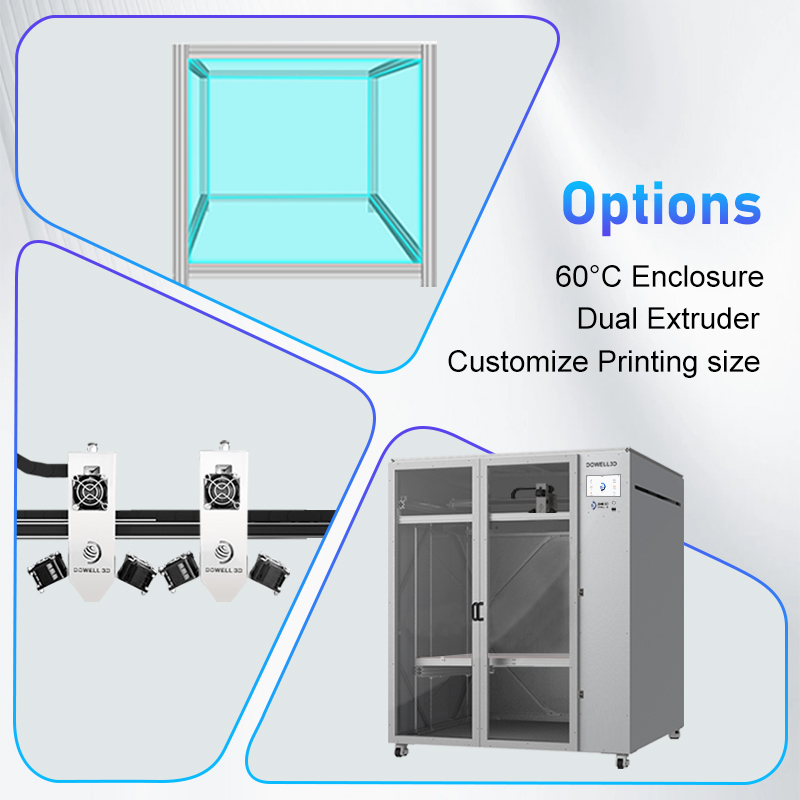

| Optional | *60℃ Enclosure *Dual extruder *Customize printing size | |||

Product Description of DOWELL3D DM-Pro Series Printer

Efficient Extrusion System & High Extrusion Flow Rate

*High-tech four drive gears offering more control, sharper details, and superior performance for

any type of filament.

*Proximal feeder extrusion flow rate max 1000g/hour, Shortens a lot of printing time on a large model.

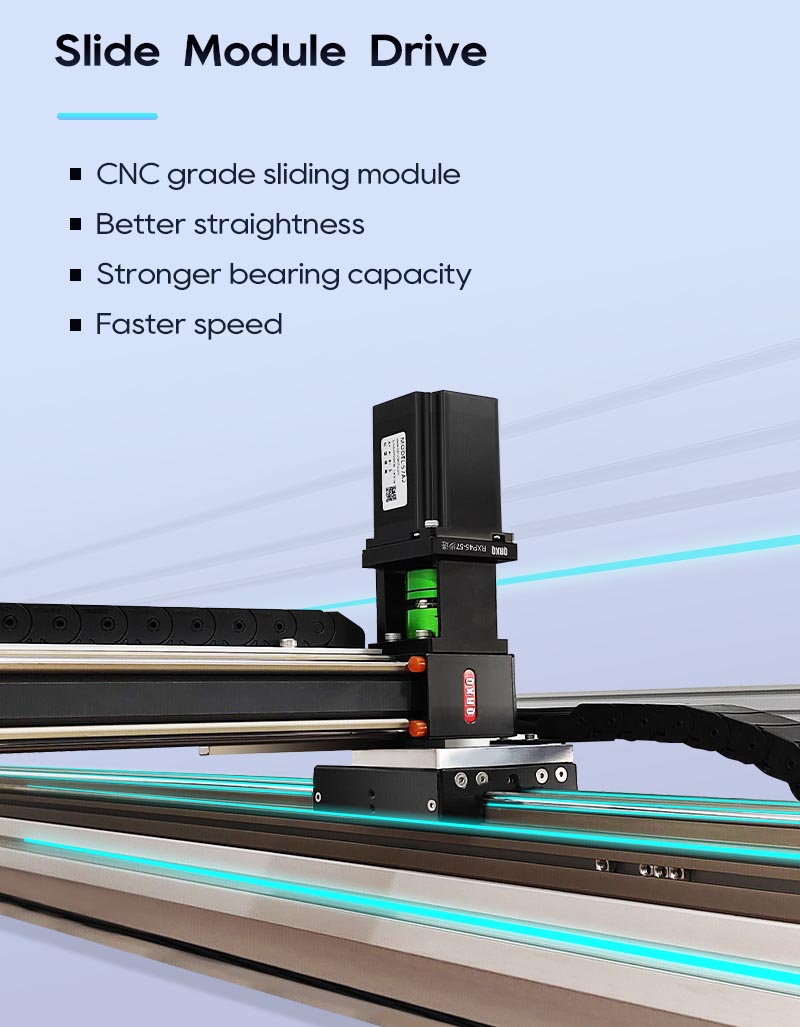

500mm/s Fast Printing Speed

The DM Pro series of industrial 3D printers boasts a high-speed print speed of 500mm/s and utilizes

a CNC-grade sliding module to provide greater straightness, greater load capacity, faster speed,

and higher precision.

Industrial Grade Sliding Platform Module Drive

*CNC grade sliding module *Better straightness *Stronger bearing capacity *Faster speed

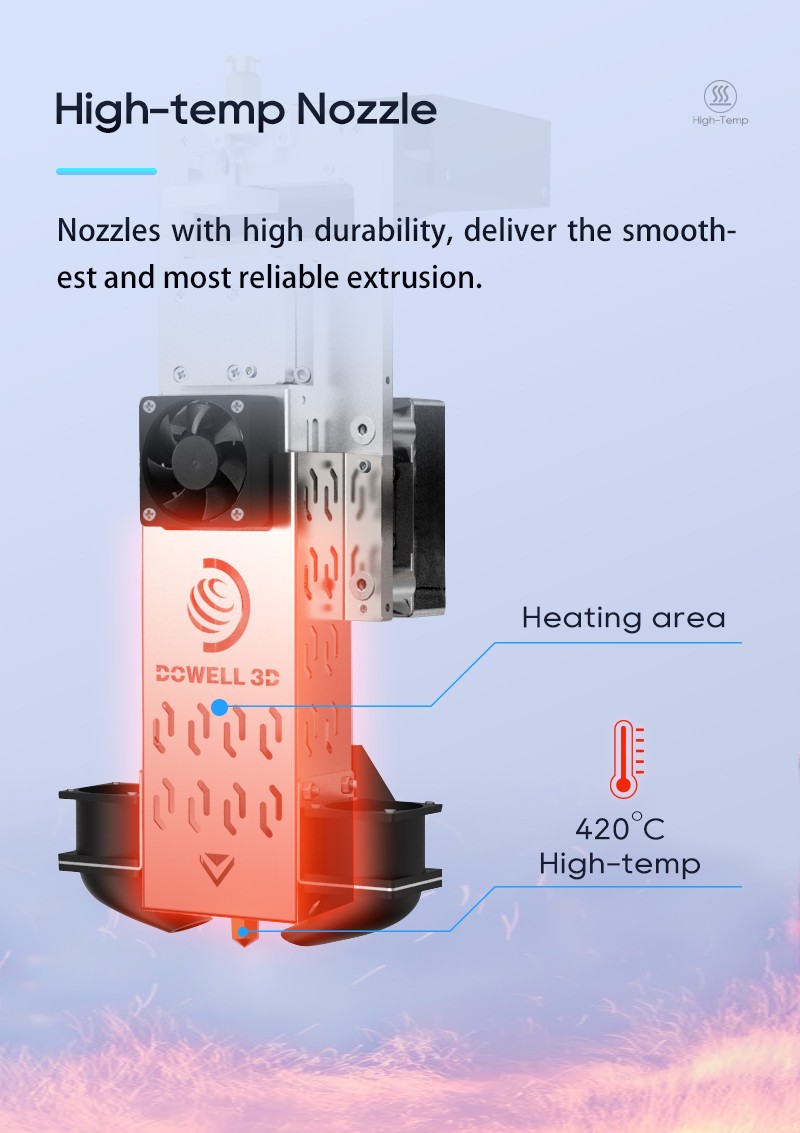

420℃ High-Temp Nozzle

The DM Pro series printers are equipped with a 420°C high-temperature nozzle that can quickly

and fully plasticize a variety of high-performance engineering filaments such as nylon, ABS, and

carbon fiber reinforced materials, achieving better layer adhesion, increasing printing speed

and the efficiency of printing complex structures.

Standard brass nozzles are ideal for general-purpose 3D printing, but abrasive filaments like nylon,

ABS, and carbon fiber require high-performance nozzles. Contact us for more options.

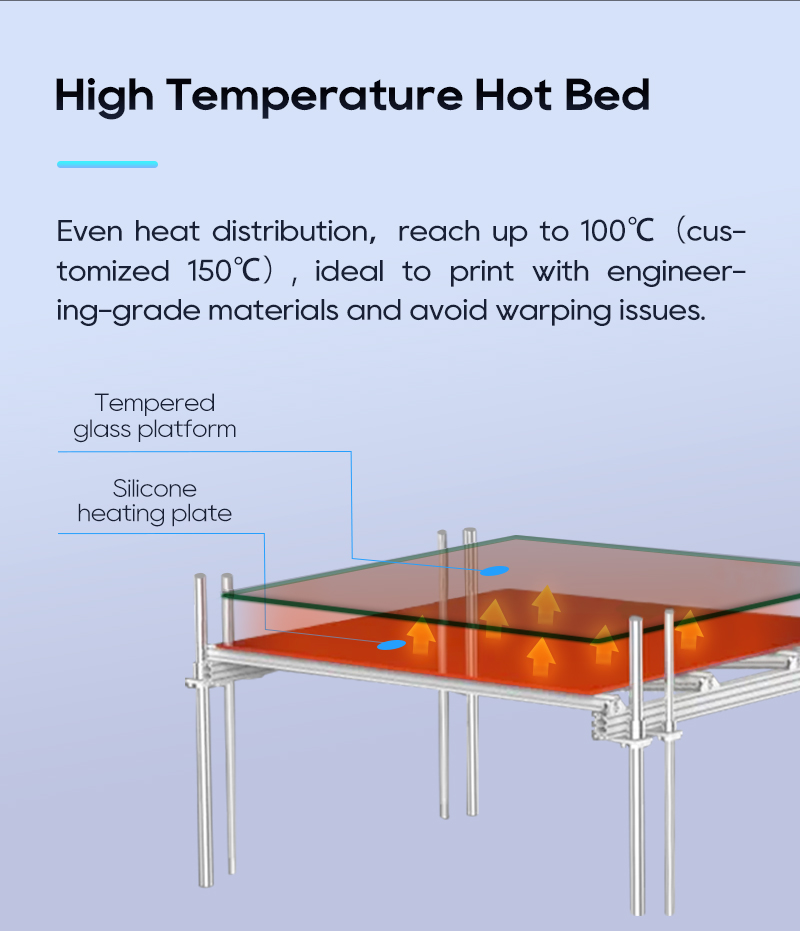

High Temperature Hot Bed

The platform is composed of a silicone heating plate and tempered glass, providing uniform

heating and precise temperature control from 0-100°C. This improves the adhesion of the first

printed layer and effectively prevents warping and peeling of models during printing.

The smooth surface of the glass platform is easy to clean, maintain, and remove models, and

has a strong load-bearing capacity.

High-precision automatic leveling system helps you operate easily

This 3D printer uses sensors to detect bed height and one-click calibration to eliminate manual

leveling errors, ensure the first layer is flat, and improve the printing success rate. It is simple

and efficient.

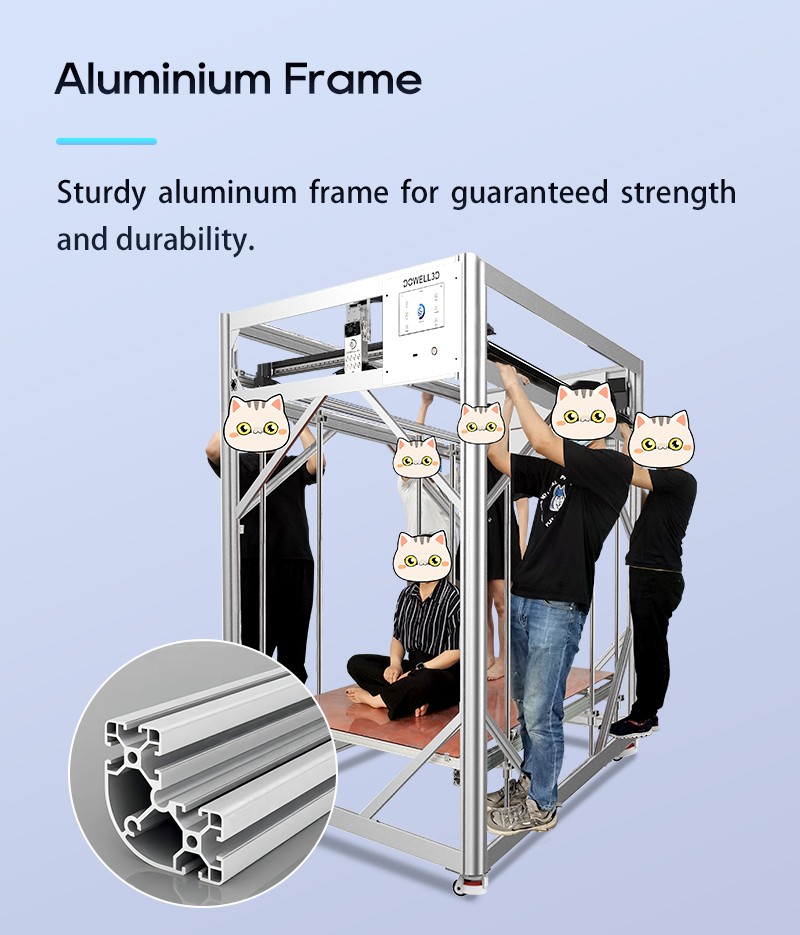

Sturdy and Lightweight Aluminum Frame

DOWELL3D High-speed DM-Pro series printer was equipped with a sturdy aluminum frame for

guaranteed strength and durability.

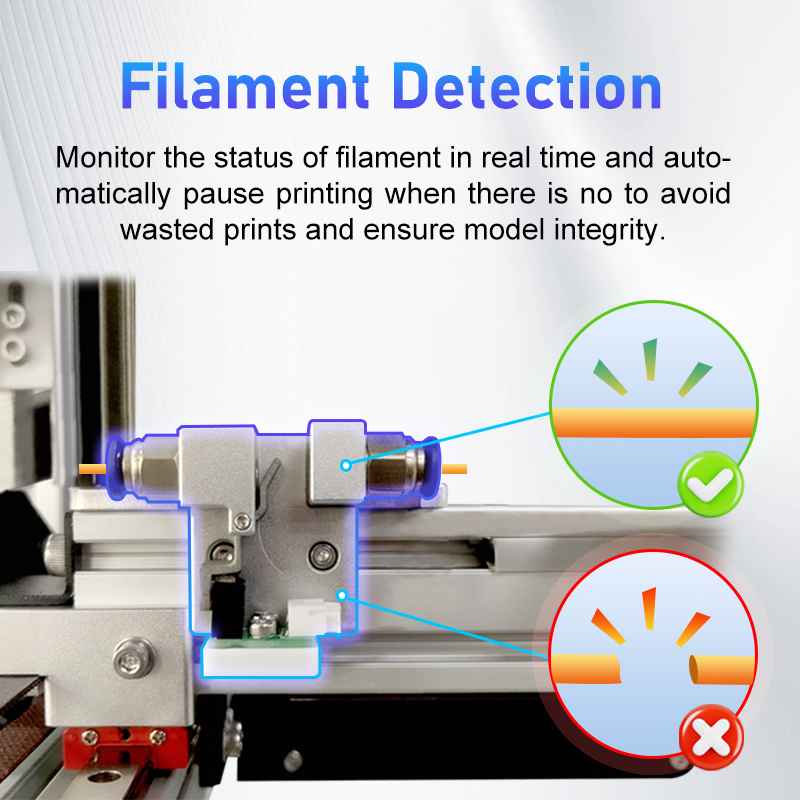

Filament Runout Sensor

This filament runout sensor is designed to detect whether your filament is run out during the

printing process.

The sensor will send the signal to the Dowell 3d printer when the filament runs out and printer

will pause the print job until the new filament is loaded.

DOWELL3D printer is equipped with remote maintenance modules to analyze possible anomalies

and to reduce the possibility of downtime for the advantage of productivity.

The remote management feature includes sending software updates to allow the DOWELL 3D

Printer to evolve over time, acquiring new features, parameters, and intelligence.

Promises:

*One year warranty *Lifetime maintenance *Factory direct sales

*Quality assurance *Technical support

Customizaton options

In addition to its fundamental features, DOWELL3D printers are also equipped with

customizable functionalities, allowing users to tailor the printer to their specific needs.

*Constant temperature enclosure *Customize printing size *Dual extruder

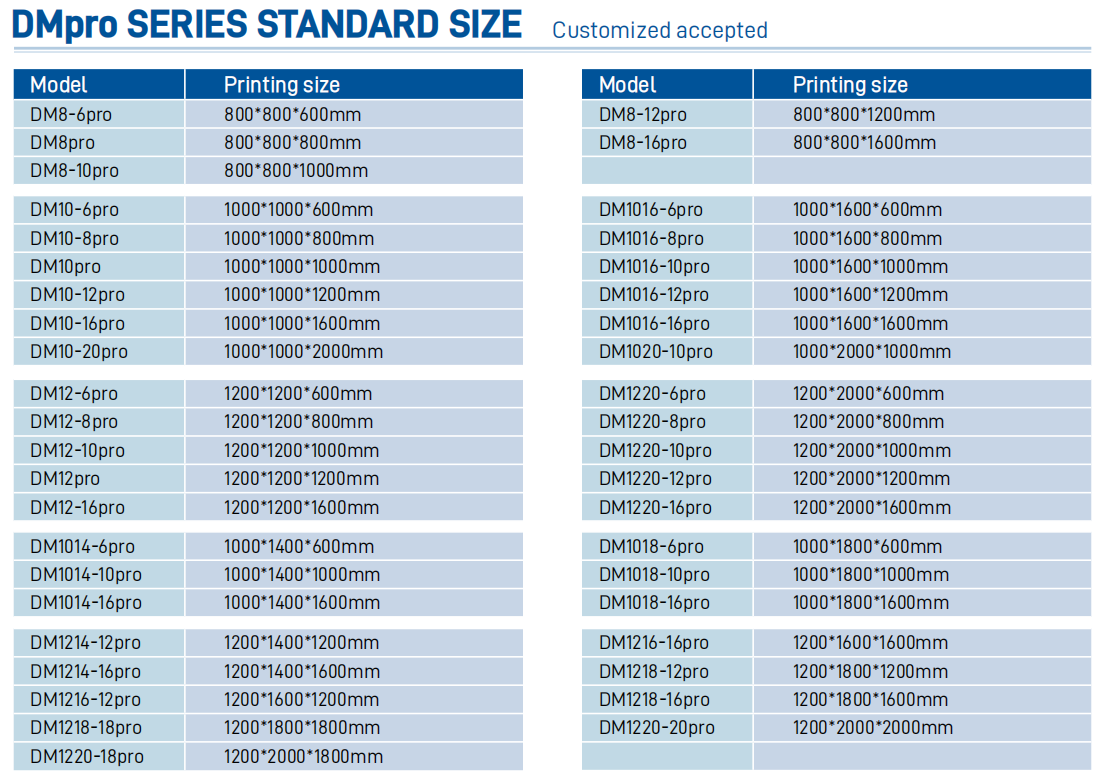

*Extensive Printer Size Options

*In addition to these sizes, you can contact us for customized dimensions tailored to your

specific requirements.

Official Notice:

Dear Valued Customers,

This is the only official store of Luoyang Dowell 3D Electronic Technology Co., Ltd.

We are the sole manufacturer and exporter of Dowell3D 3D printers and related products.

Please note:

We have not authorized any third-party websites or suppliers to distribute or resell our products.

Products sold under the "Dowell3D" brand on other platforms or websites are counterfeit and

unauthorized. They lack genuine quality, technical support, and after-sales service. Please exercise

caution and discretion when purchasing.

Choose us without hesitation; it will be the best decision you make.

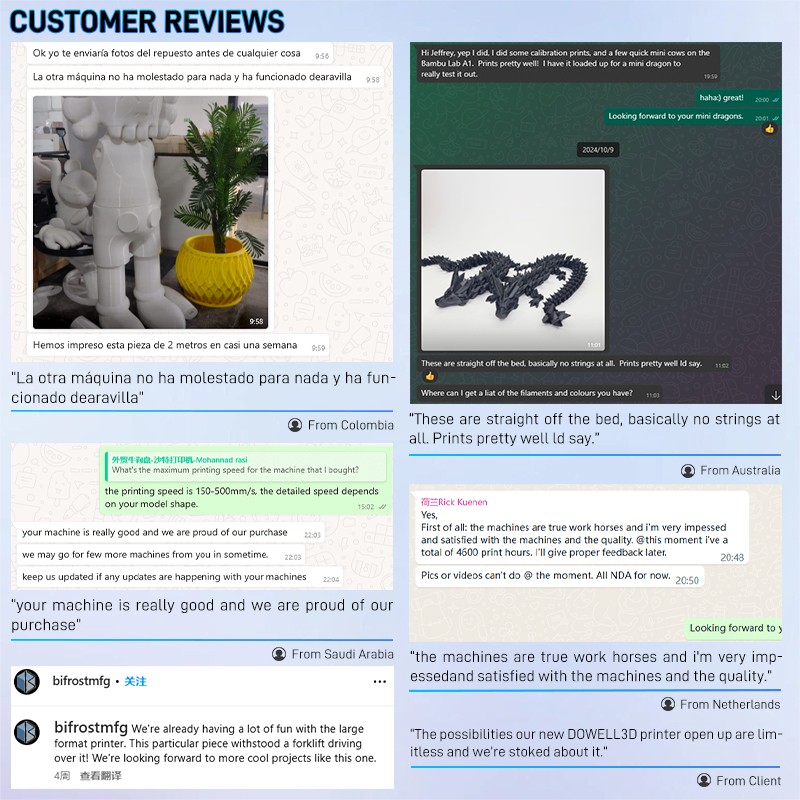

Customer's Printing Cases of DOWELL3D Printer

Company Profile & Certifications of DOWELL3D

Print with Ease, Innovate Infinitely!

Luoyang Dowell Electronic Technology Co., Ltd. was established in Luoyang, China, in 2014.

With 11 years of industry Experience, the company specializes in the research, development,

and sales of industrial-grade 3D printers, providing intelligent, high-precision, and multi-material

printing solutions. Dowell is one of the world's largest 3D printer manufacturers, trusted by

professional customers worldwide and receiving 100% positive customer reviews.

Our products are widely used in industries such as automotive, advertising signage, furniture

design, sculpture production, education, and industry. We also have a dedicated customer service

team ready to help you, answer questions, and provide support.

FAQ

1-Are you a factory?

Yes, we are a direct manufacturer focused on developing and producing large industrial 3d printers.

2-Payment method

T/T (Bank transfer), PayPal, Western Union, Credit card, WeChat Pay, Ali Pay, T/T

3-Shipping method

DHL, UPS, FedEx, TNT, sea shipping, air freight, and by train.

4-What's your lead time?

If the product you order is our standard model, lead time is around14 days; otherwise, lead time is negotiable.

5-How do you guarantee the quality of the printer?

We have 100% tests before shipment. We will supply photos and videos of tests before shipment.

We can guarantee that our 3D printer will have absolutely no quality problems before shipment.

Then we will arrange the shipping under the confirming.