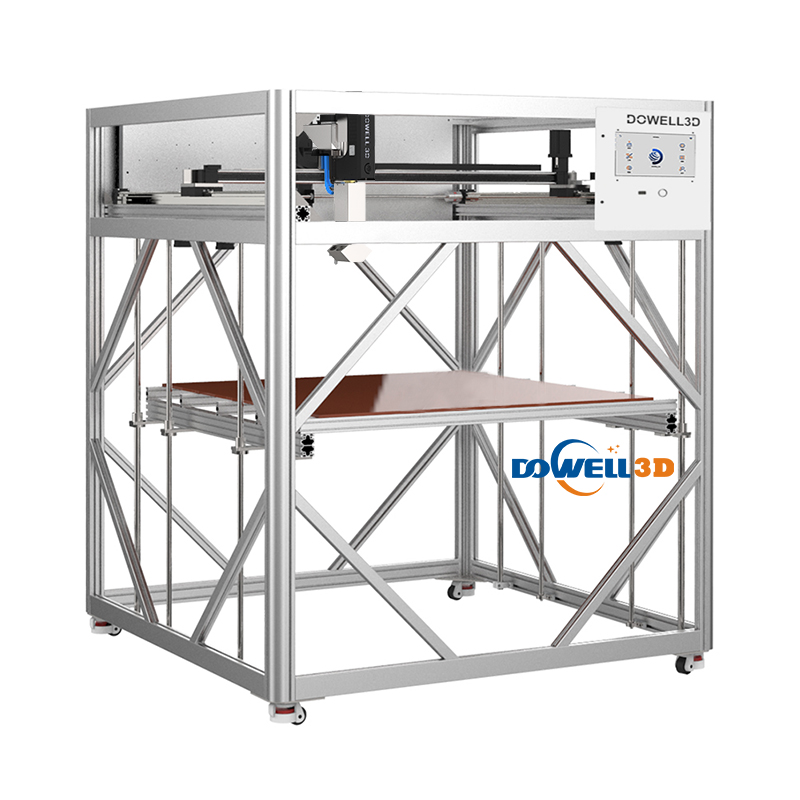

Dowell Pellet Extruder 3d Printer 1600*1600*1200mm Large Auto Leveling FGF PP Granule 3d Printer

- DOWELL3D

- China

- 10-16 days

- 1000 set/month

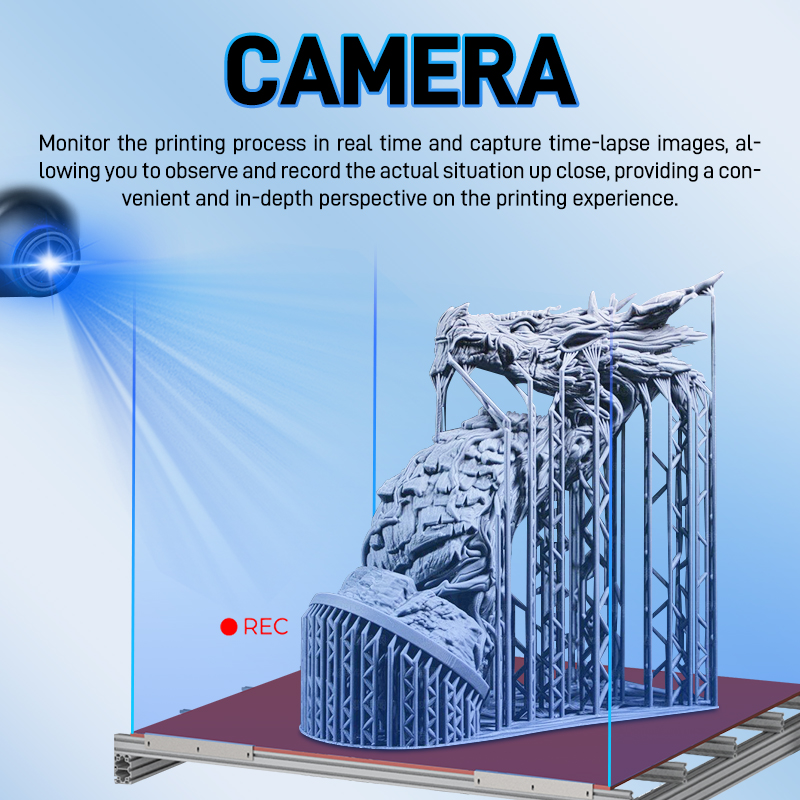

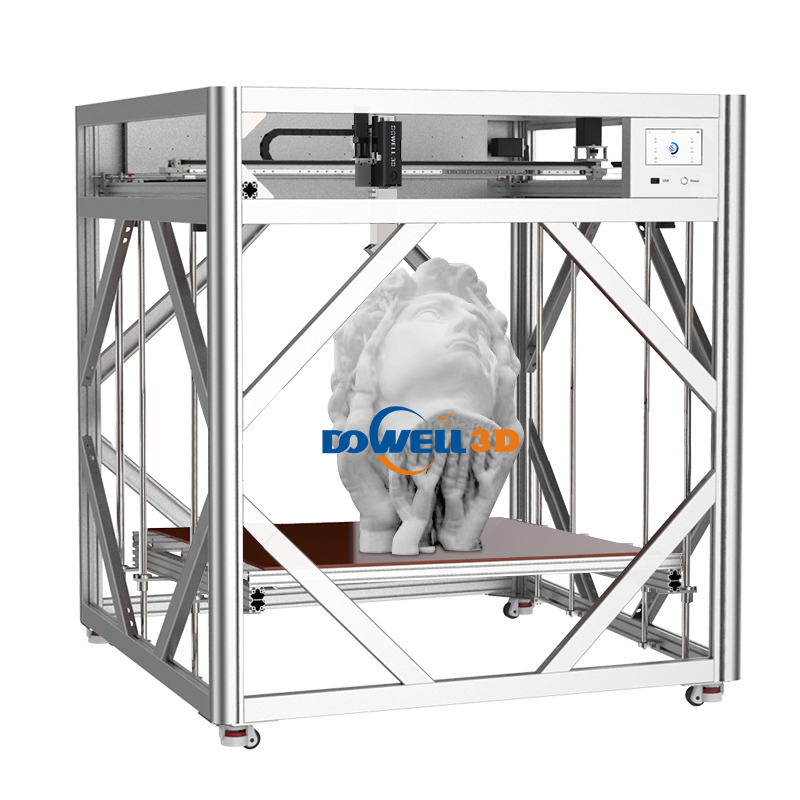

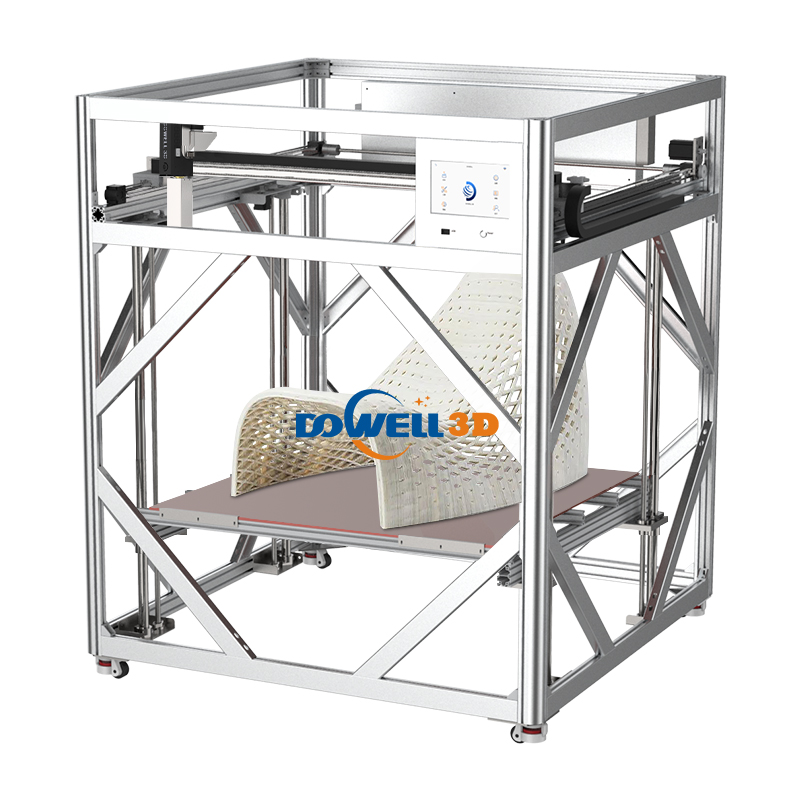

The Dowell DP-A1616-12 pellet 3D printer offers large-format, high-speed, screw extrusion printing with a build volume of up to 1600*1600*1200 mm and a high extrusion rate of 4000-5000 g/hour. It features automatic feeding, a heated bed, a 420°C high-temperature nozzle, and 3-level temperature control, supporting the printing of a variety of pellets, including PLA, ABS, and PP. It also features intelligent automatic leveling, a water cooling system, remote management, and camera capabilities.

DOWELL3D

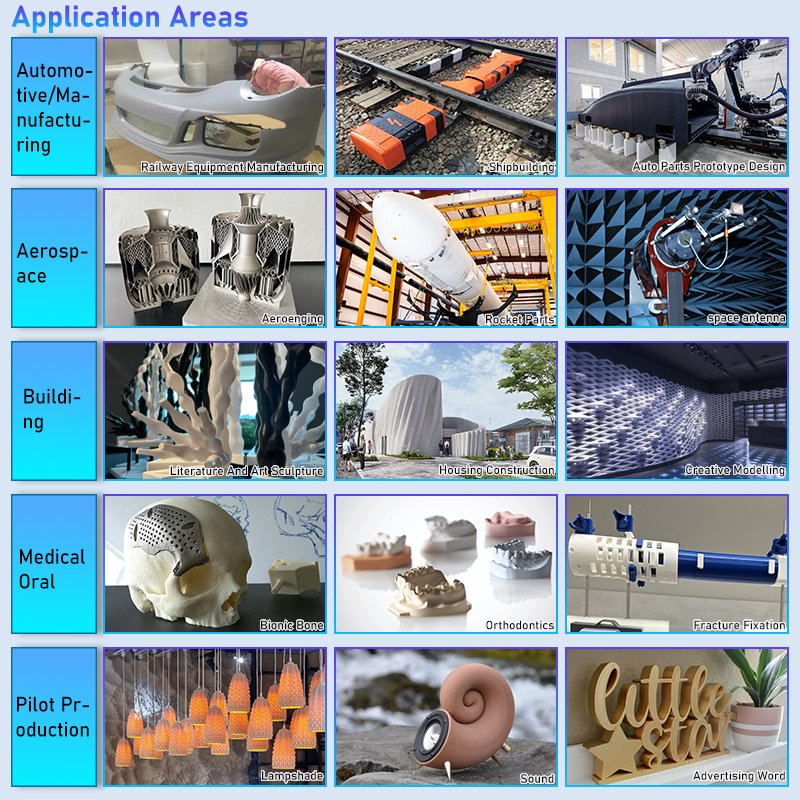

Dowell is a technology-driven company committed to innovation and sustainable development, specializing

in providing high-quality, environmentally friendly 3D printing filaments, as well as large-format industrial-grade 3D printers.

These products include specialized equipment such as sculpture printers, automotive printers, pellet printers,

and furniture printers. The company's solutions are widely used in industries such as automotive, aerospace,

biomedical, advertising signage, mold manufacturing, furniture design, and sculpture production.

Industrial Grade FGF Pellet 3d Printers

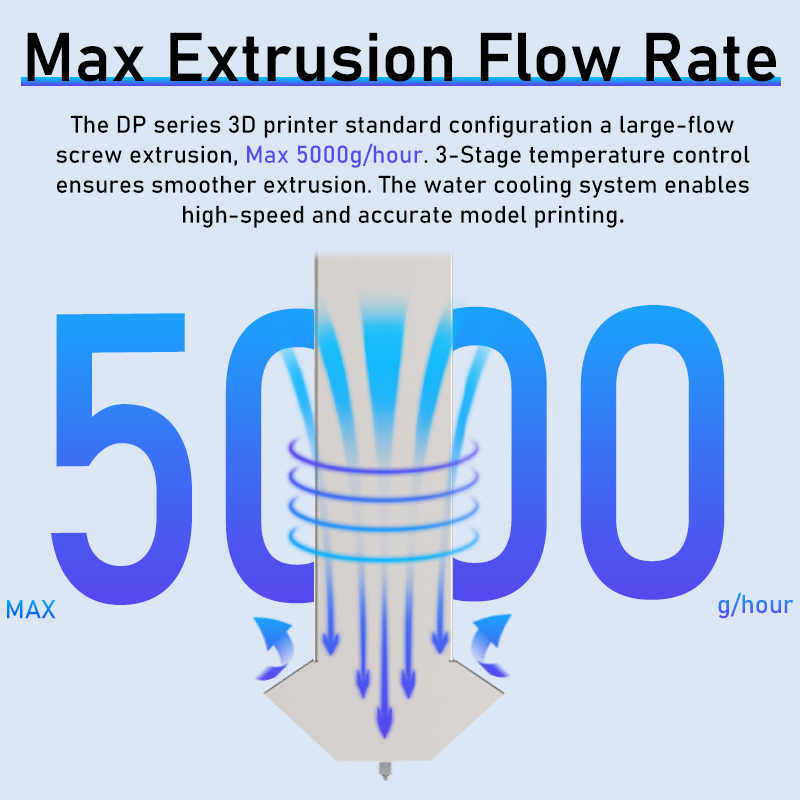

The Dowell pellet 3D printer is a large-format, high-speed thermoplastic extrusion printer with a maximum

extrusion flow rate of up to 5000 mm/h and a printing speed of 250 mm/s. It can print quickly without waiting,

and the nozzle can be heated to 420°C in 35 seconds, saving you valuable time.

It is particularly suited for creating sizable patterns, molds, tooling, jigs, fixtures, batch production runs, and

full-scale prototypes.

If you want to know more about the product information and price of the FGF DP-A particle 3D printer,

Please click to consult, and we will have professional product consultants to answer your questions.

| Product Name | FGF Industrial Pellet 3d Printer DP-A1616-12 |

| Molding technology | Fused granulate fabrication(FGF) |

| Molding size | 1600*1600*1200mm |

| Frame | 80mm thickened aluminum section |

| Feeding system | Automatic feeding |

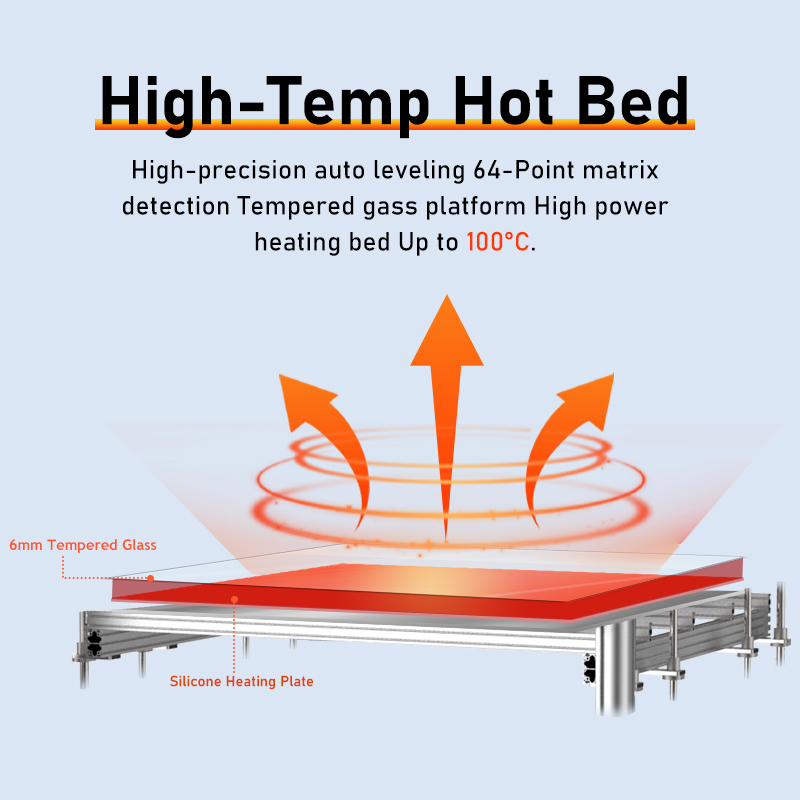

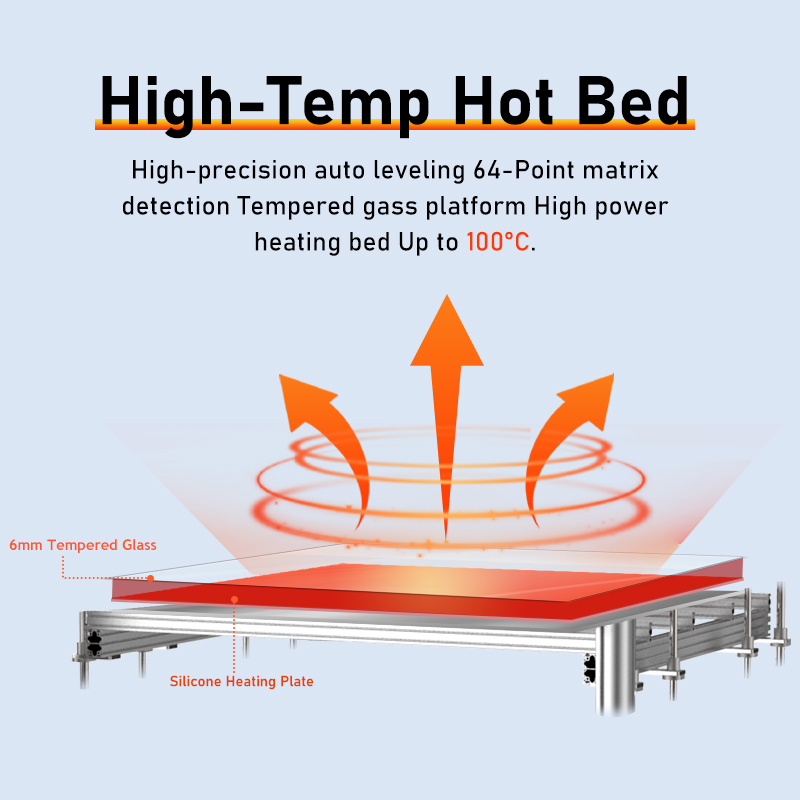

| Bed temperature | 6mm tempered glass 0-100℃ |

| Printing Material | pellet<Φ4mm recommended |

| Nozzle diameter | 1.0/2.0/3.0 mm |

| Extruder | 3 Stage Screw extrusion, automatic feeding system |

| Max extrusion flow rate | 4000-5000g/hour |

| Printing speed | 0-300mm/s |

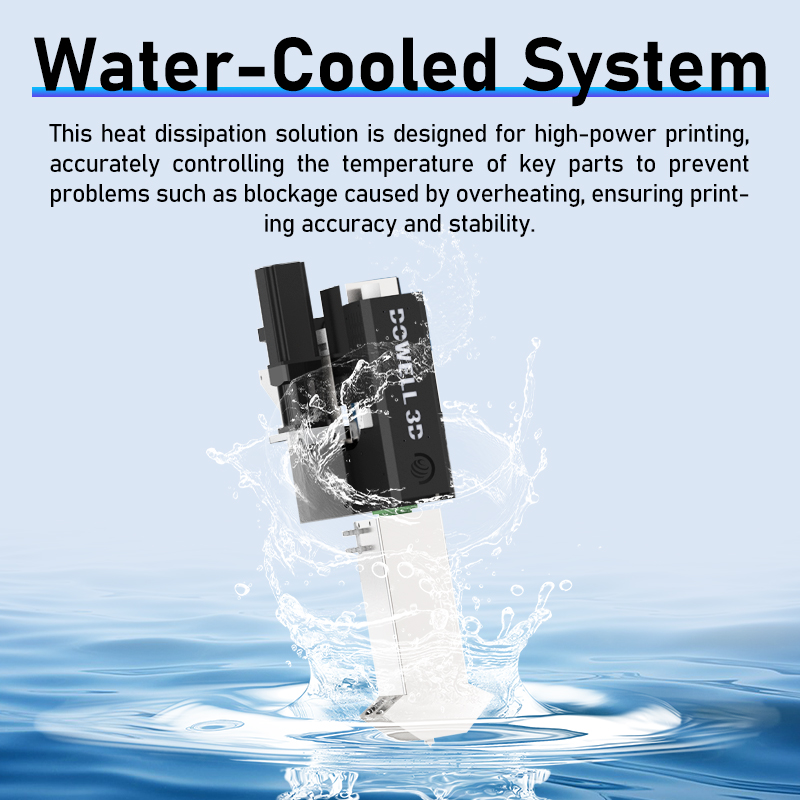

| Extruder cooling system | Water cooling |

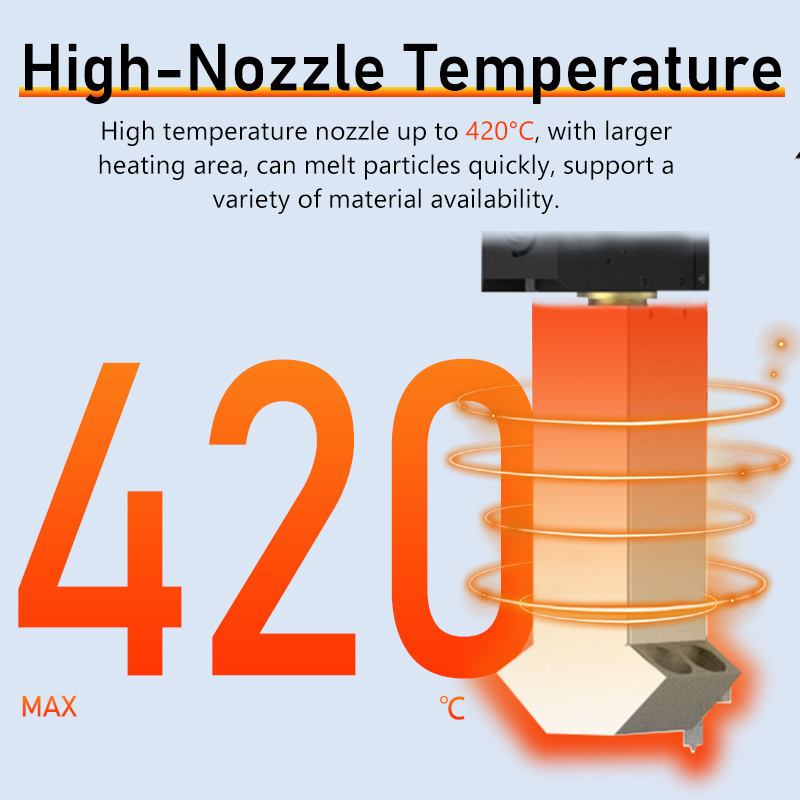

| Nozzle temperature | 0-420℃ |

| Operation interface | 10''full color touch screen |

| File format | STL/OBJ/GCODE/JPG |

| Input power | 110V/220V |

| Basic functions | *Auto leveling *Remote control *Automatic feeding system *Water cooling *Wifi connection *Visible Printing status *Visible temperature graph *Installable external camera *Configuration editable *Z-offset adjustment *Speed & extrusion & cooling adjustment *Gcode viewer *History record *Emergency stop button *Automatic temperature control |

| Customization options | *60°c enclosure *Printing size |

Product Description

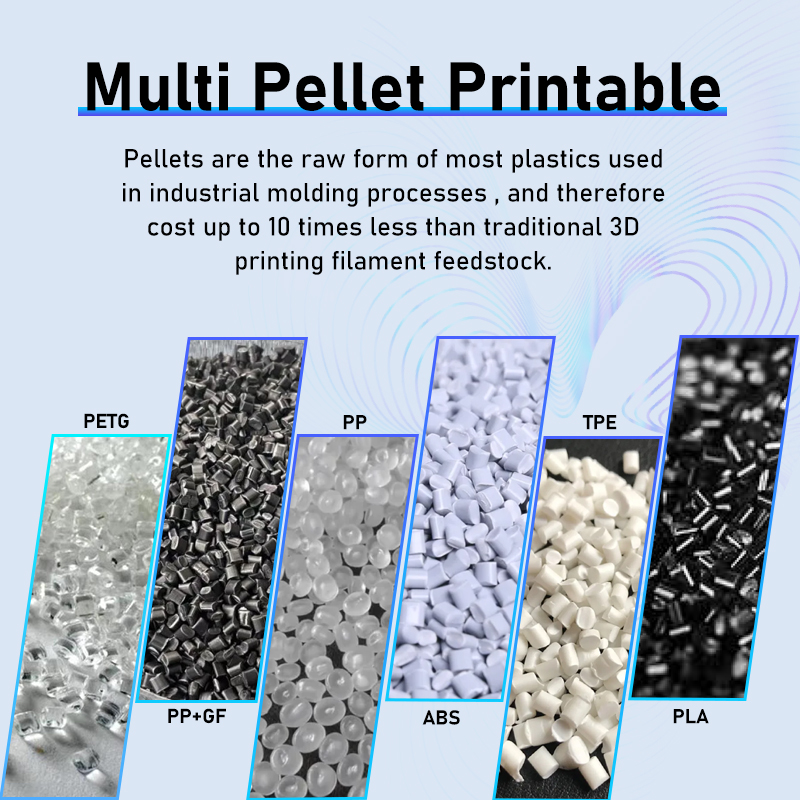

Various Pellet Materials Available

Pellets are the raw material for most plastics used in industrial molding processes. Our DP-A series printers

create excellent conditions for pellet printing, enabling rapid heating and extrusion of materials ranging from

PLA to high-temperature engineering-grade thermoplastics. This provides strong support for industrial composite pellet printing.

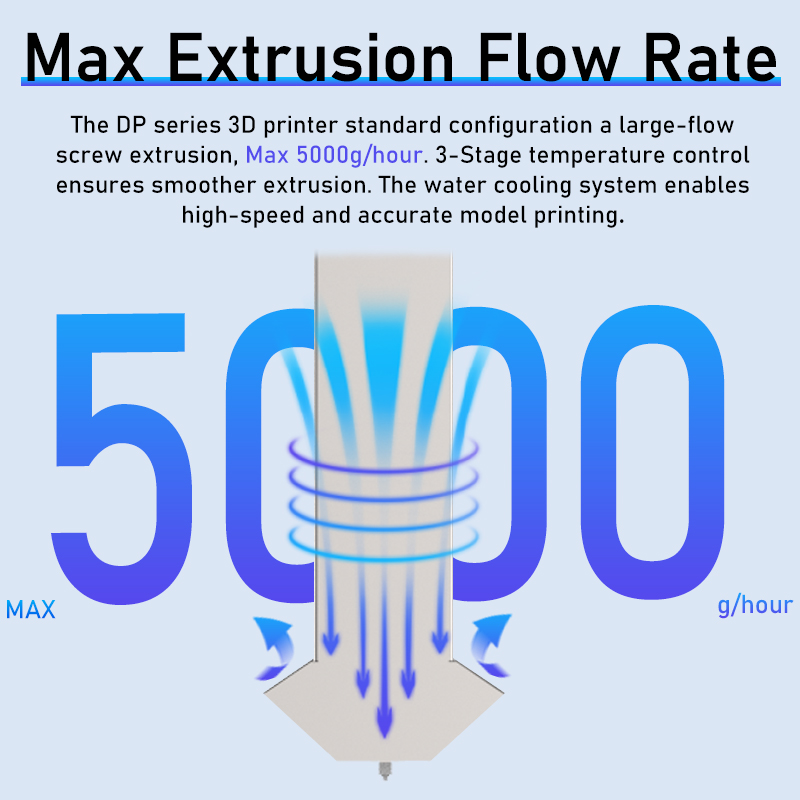

High Flow Screw Extrusion

The DP-A features a pioneering screw extrusion system, revolutionizing large-format 3D printing with its powerful,

even extrusion force for uniform material flow and adhesion. It offers versatile slice thicknesses and nozzle sizes

(1.2-3.0mm), enabling both fine details and high flow rates (up to 5000g/h), enhancing print quality and flexibility.

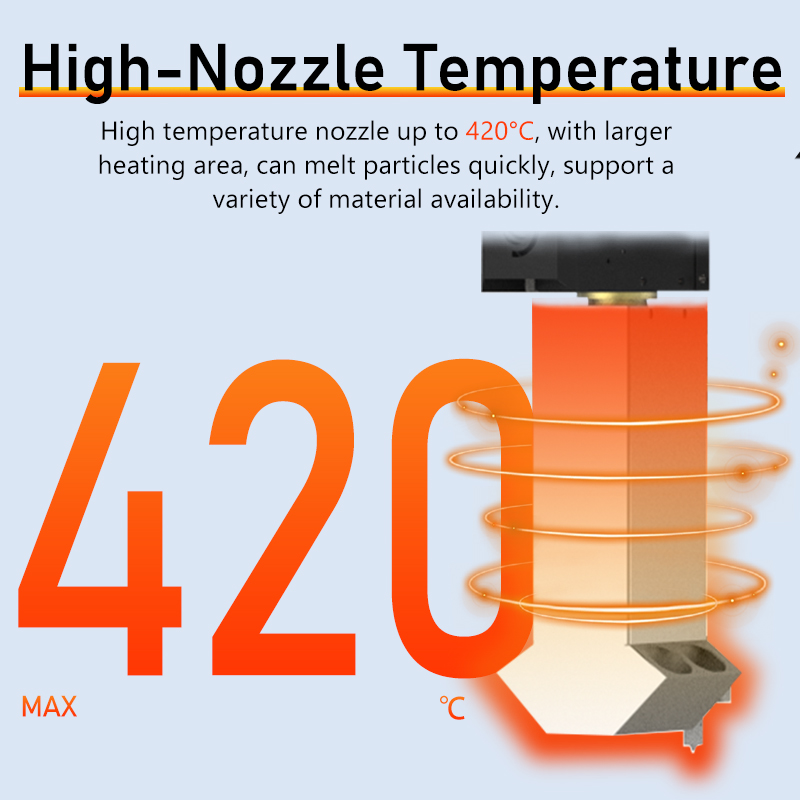

420℃ High temp nozzle

With a nozzle temperature reaching up to 420°C and a bed temperature of ≤100°C, the DP-A FGF Pellet 3D

Printer's nozzle is designed to handle high-temperature materials. This enables the printer to work with a wide

array of thermoplastics and composite materials, including PLA, PETG, ABS, TPE, and composite materials,

broadening the horizon for creating durable, complex parts with ease.

Excellent and stable heating platform

Silicone Heating Plate + 6mm Tempered Glass Platform

The entire bed surface utilizes a silicone rubber heating plate for even and rapid heating, reducing printing wait times.

Precise temperature control from 0-100°C effectively prevents warping and boasts a load-bearing capacity

exceeding hundreds of kilograms.

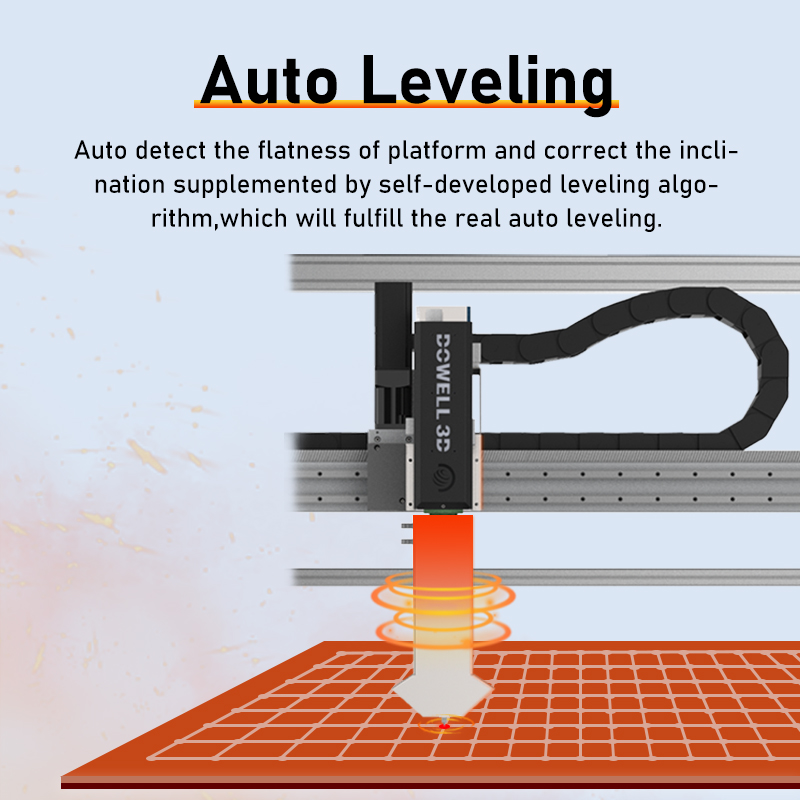

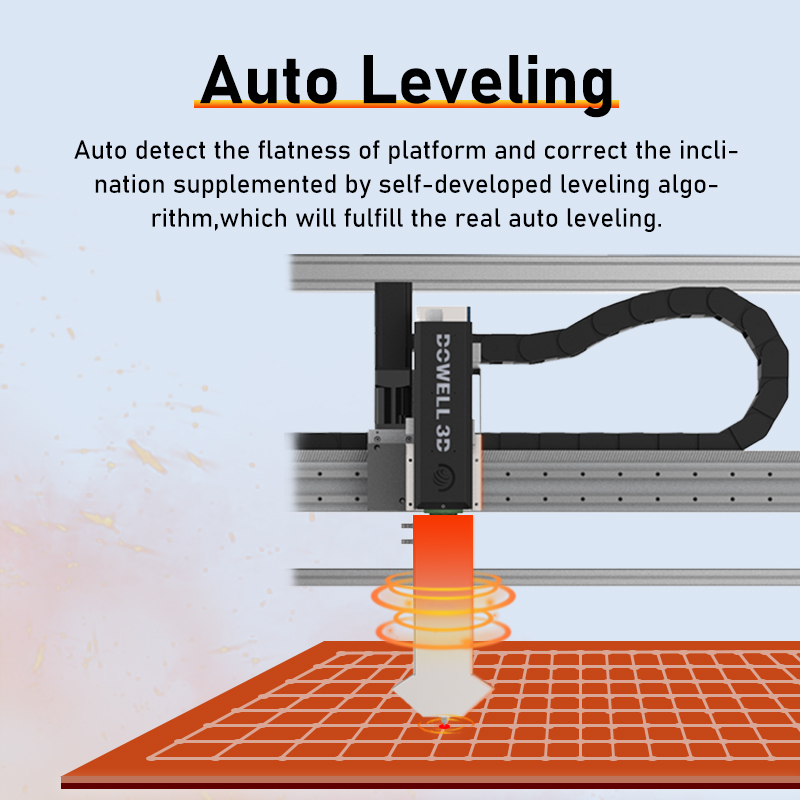

One key auto-leveling helps you operate easily

The DP-A Pellet 3D printer features a high-precision sensor-based auto-leveling system,

Allowing the nozzle to automatically detect platform height. Real-time algorithm

adjustments make the printing process effortless and convenient.

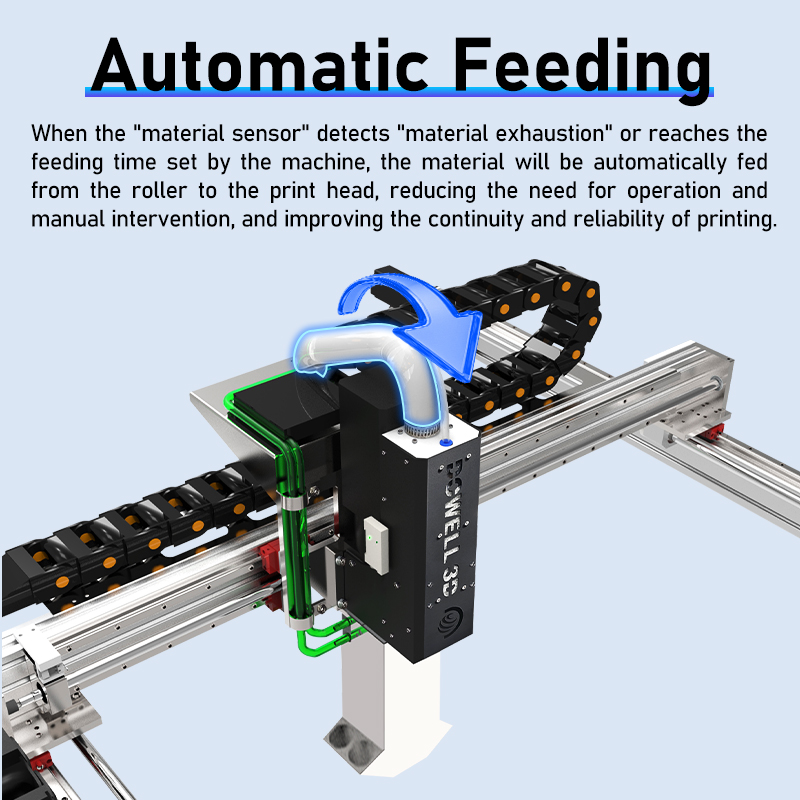

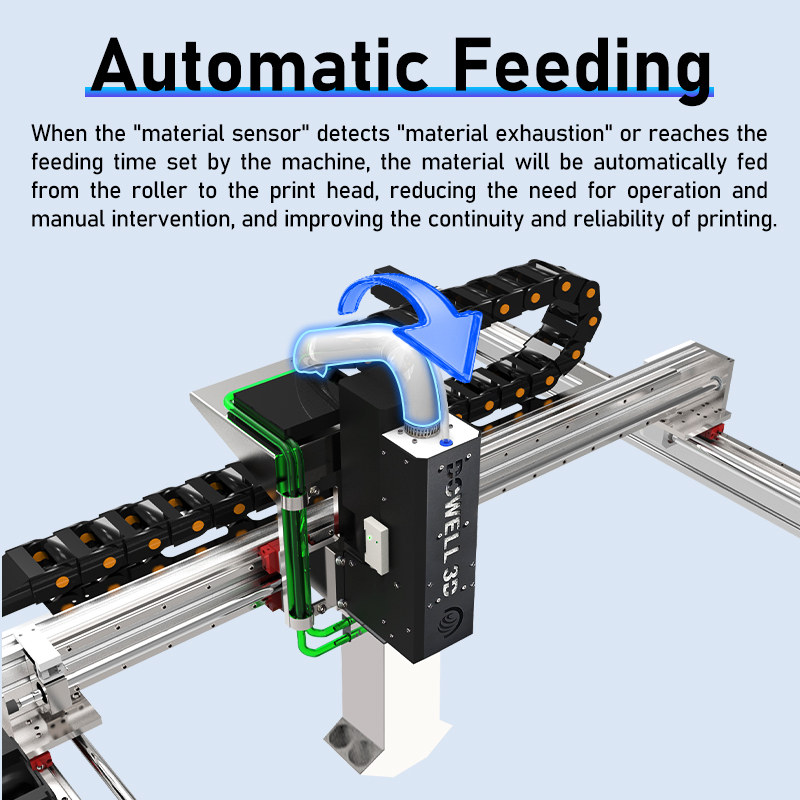

Automatic feeding

When the "material sensor" detects "material exhaustion" or reaches the feeding time set by the machine, the

material will be automatically fed from the roller to the print head, reducing the need for operation and manual

intervention, and improving the continuity and reliability of printing.

Water-Cooled System

This heat dissipation solution is designed for high-power printing, accurately controlling the temperature of

key parts to prevent problems such as blockage caused by overheating, ensuring printing accuracy and stability.

WiFi connectivity and remote control

Remotely connect to your printer, print files directly, and monitor the printing status in real time, making printing

easier and more convenient. Technicians can also remotely connect to your printer for system updates and

maintenance. Make printing easy.

Large Workspace

The DP-A pellet 3D printer boasts a large workspace, measuring up to 1600 x 2400 x 1600 mm, providing ample

space for producing a variety of large parts.

The spacious build area is ideal for creating large models, full-scale molds, and numerous functional prototypes.

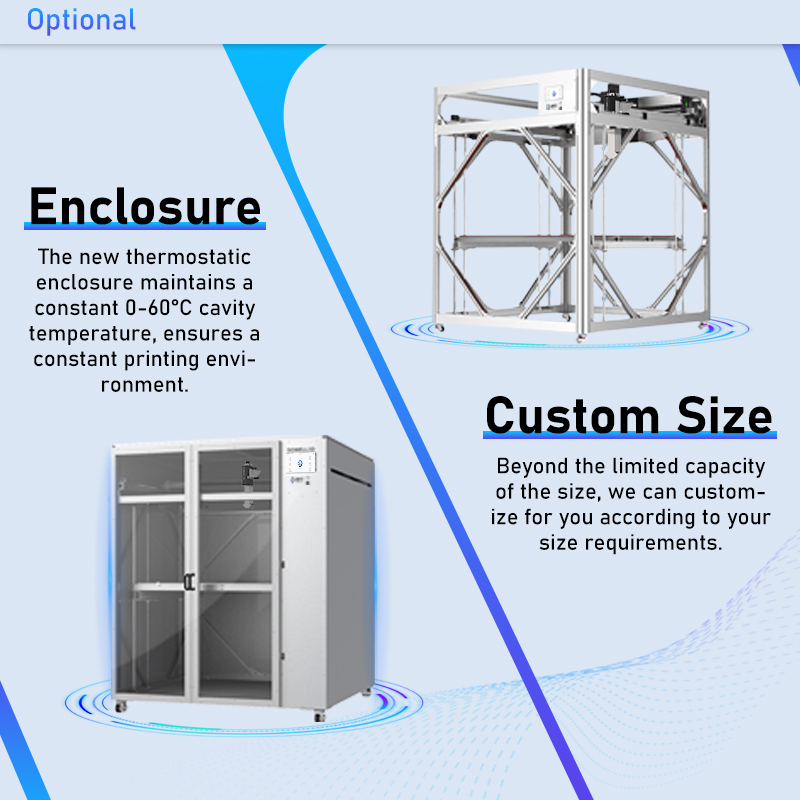

Customization options

1. Constant temp Enclosure

The heater located at the bottom of the structure generates a uniform heat flow, keeping the temperature in the

chamber constant at 60°C, effectively preventing deformation and warping of high-shrinkage materials during printing.

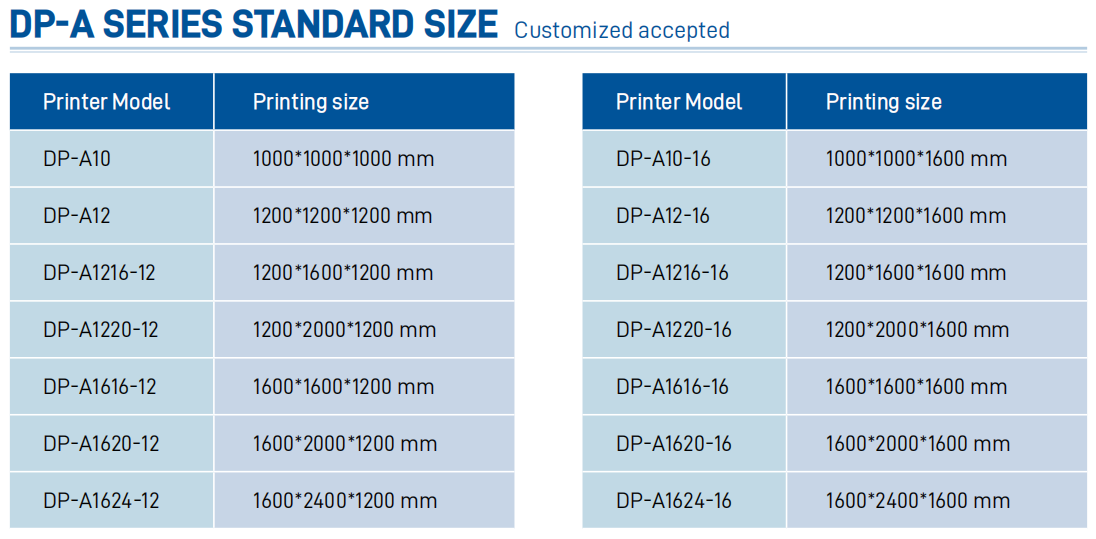

2 . Custom Sizes

In addition to the 14 standard sizes, we can also customize your size.

Official Notice:

Dear Valued Customers,

This is the only official store of Luoyang Dowell 3D Electronic Technology Co., Ltd.

We are the sole manufacturer and exporter of Dowell3D 3D printers and related products.

Please note:

We have not authorized any third-party websites or suppliers to distribute or resell our products.

Products sold under the "Dowell3D" brand on other platforms or websites are counterfeit and unauthorized.

They lack genuine quality, technical support, and after-sales service. Please exercise caution and discretion

when purchasing.

Choose us without hesitation; it will be the best decision you make.

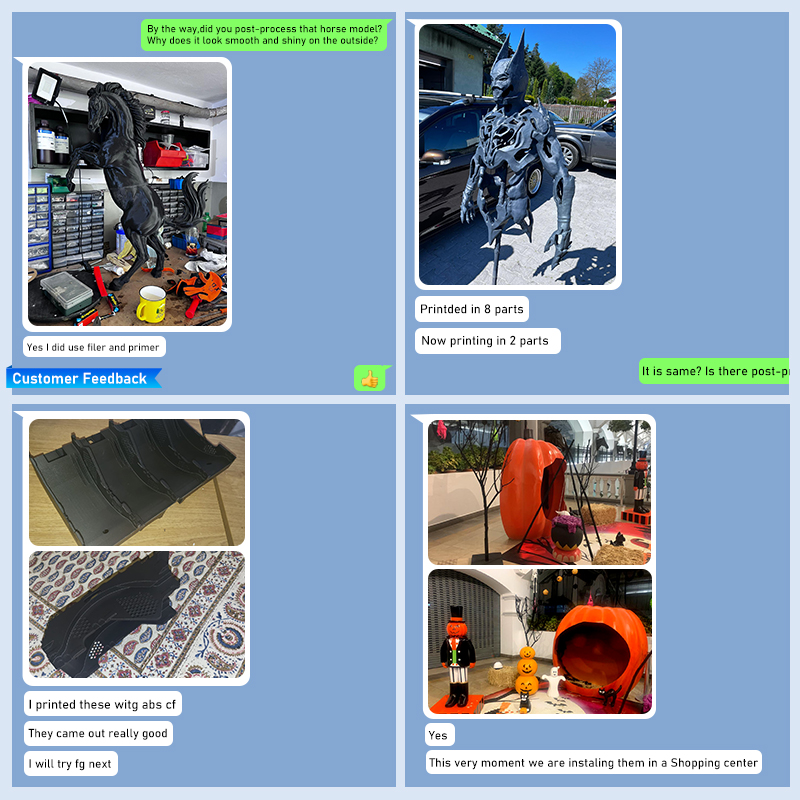

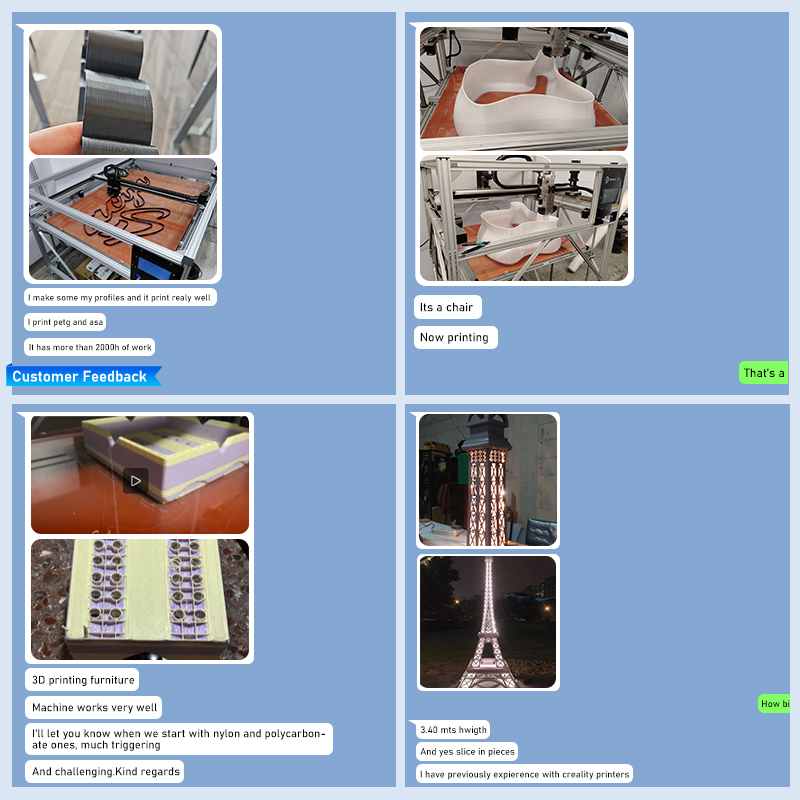

Customer Feedback

Why Choose FGF Pellet 3D Printer?

1. Reduce Costs

Pellet extrusion 3D printing offers significant savings, cutting costs up to 10X compared to traditional filament-

based methods.

2. Shorten Lead Times

Enjoy speeds up to 10X faster than conventional filament extrusion 3D printing, drastically reducing project

lead times.

3. Excellent Material Properties

Use original materials for optimal material properties, ensuring enhanced performance of printed components

through superior quality.

4. Eco-Friendly

Our 3D printing innovation uses pellets and shredded recycled plastic for sustainable, eco-friendly additive

manufacturing alternatives.

FAQ

1. Are you a trading company or a manufacturer?

We are DOWELL, a 3D printer manufacturer with over 11 years of R&D experience.

2. What certifications do you have?

CE, FCC, ROHS, etc.

3. Do you have proprietary software?

Yes, we have a strong R&D team that uses Dowell's proprietary software and will provide guidance on how to use it.

4. What services do we provide?

Delivery terms accepted: EXW, FOB, CFR, CIF, DDP, DDU

Shipping methods accepted: Sea freight, Air freight, DHL. FedEx, UPS

Accepted payment currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY

5. Is there a warranty for overseas customers?

Yes, the machine comes with a one-year warranty. We have professional technical engineers and instructional videos.

The machine is fully automatic and easy to operate.

6. How long does it take to print a part with the Dowell FGF 3D printer?

Printing time depends on the item's material, shape, and size.

The Dowell FGF 3D printer is equipped with a proprietary extruder and a large nozzle, providing strong and stable

extrusion output, resulting in superior printing performance compared to similar products on the market.