FDM vs. FGF 3D Printers: A Comprehensive Guide to Choosing Your Technology

3D printing technology has revolutionized the manufacturing industry, and understanding the differences between fused

deposition modeling (FDM) and fused granular fabrication (FGF) are crucial for choosing the right method for your project.

This article delves into the unique properties, applications, and cost considerations of FDM and FGF 3D printing technologies.

What is FDM 3D Printing?

FDM (fused deposition modeling) is an additive manufacturing process and a common 3D printing technology. It uses a coiled

plastic filament as feedstock. A spool of filament is fed into a heated extruder and nozzle, which deposits molten plastic onto a

build platform. The nozzle then moves, extruding the molten thermoplastic filament layer by layer from the bottom up to create 3D objects.

This widely used, cost-effective technology, capable of producing high-resolution, detailed prints, is renowned for its speed,

wide range of materials, and ability to create prototypes, tools, and end-use parts for a wide range of industries. It is suitable

for a wide range of applications, from prototyping to low-volume production. A wide selection of filaments, such as PLA,

ABS, ASA, NYLON, PP, TPU, PVA, PETG, WOOD, CARBON FIBER, and GLASS FIBER ... further enhance the versatility of FDM printing.

Furthermore, the ease of use and widespread availability of FDM printers and filaments make them ideal for hobbyists,

educational institutions, and professional applications.

What is FGF 3D Printing?

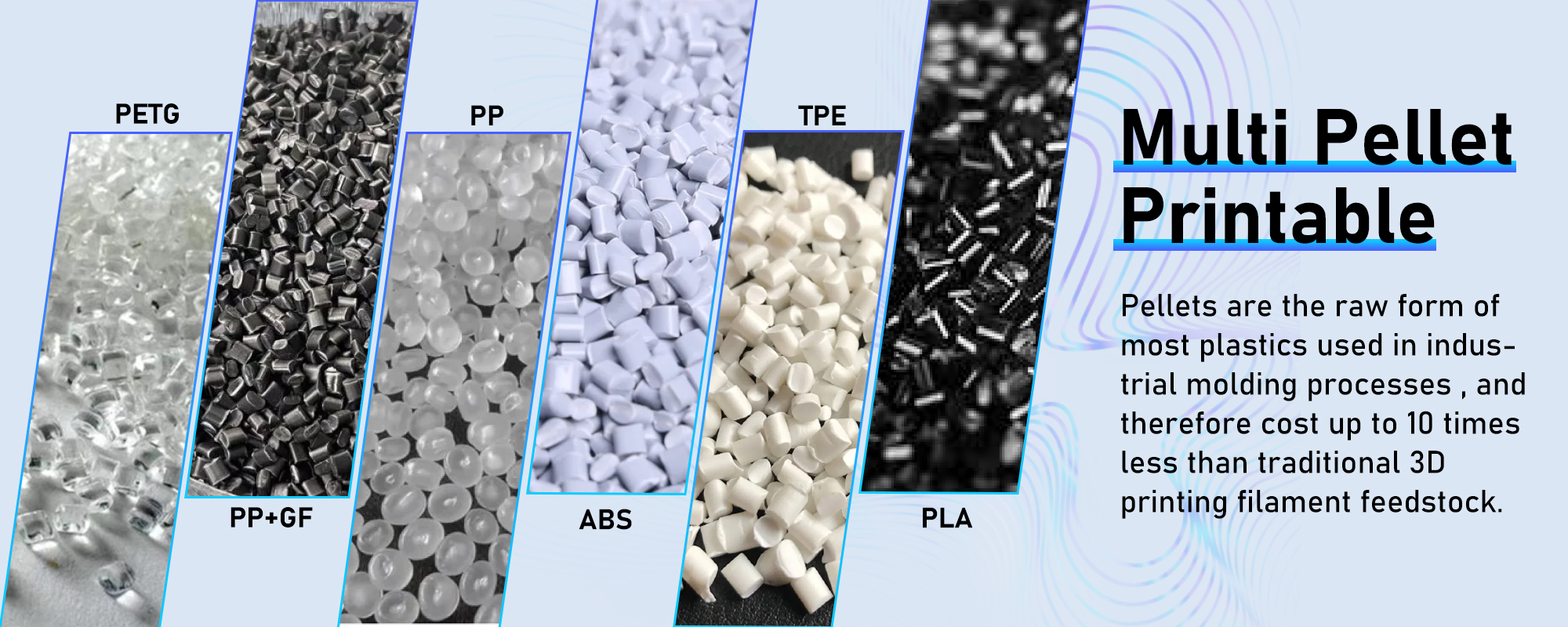

Fused Granulate Fabrication (FGF) is a 3D printing technology that uses plastic pellets as the primary material. This method involves

feeding granulated thermoplastic into an extruder, which melts the granules and deposits the molten material layer by layer to create

the final object. The FGF 3d printer is known for its ability to print large-scale objects quickly and affordably, making it ideal for industrial applications.

The FGF printing machine stands out because it can utilize a wide variety of thermoplastic materials, including recycled plastics, which significantly reduces

material costs. The use of pellets instead of filaments allows for high throughput, making the FGF printer suitable for large-scale production.

Additionally, the ability to use recycled and lower-cost materials makes FGF an environmentally friendly and economically viable option for many manufacturers.

What is the Difference Between FDM and FGF?

| FDM 3D PRINTER | FGF 3D PRINTER | |

| Material | Uses a plastic filament (spool of plastic string) | Uses plastic pellets or granules |

| Material Cost | Pellets can be 30% cheaper per kilogram than filament. | |

| Process | The filament is fed into a heated nozzle, melted, and extruded layer by layer. | Pellets are fed directly into a heated extruder, melted, and then extruded at a high rate. |

Print Resolution | Higher print resolution and finer detail | Lower resolution |

| Print Speed & Throughput | High speed and high extrusion flow rate explain why FGF's material throughput is several times higher than FDM. | |

| Print Quality & Detail | FDM printer generally excels at producing fine details and complex geometries | FGF printer is better suited for larger parts where ultra-fine detail is less critical |

| Disadvantages | Slower for large parts due to limitations in material output, and can be prone to filament jams. | Lower resolution compared to FDM due to the larger material output. |

| Best for | Prototyping, small-scale production, and detailed models. | Industrial applications, large-format 3D printing, and high-volume production, where speed and cost are more critical than fine detail. |

Which One is Right for You?

Fused Grain Forming (FGF) and Fused Deposition Modeling (FDM) offer distinct advantages in different applications.

FDM is recommended for detailed prototypes, complex models, and high-resolution models.

FGF is recommended for large prototypes, full-scale functional parts, molds, and applications where low material cost and high production volume are important.

If you want to know more about the DOWELL 3D printer, please contact us or

leave a message, and we will explain it to you in detail.