Beyond Filament: 5 Innovative Applications of FGF Pellet 3D Printing

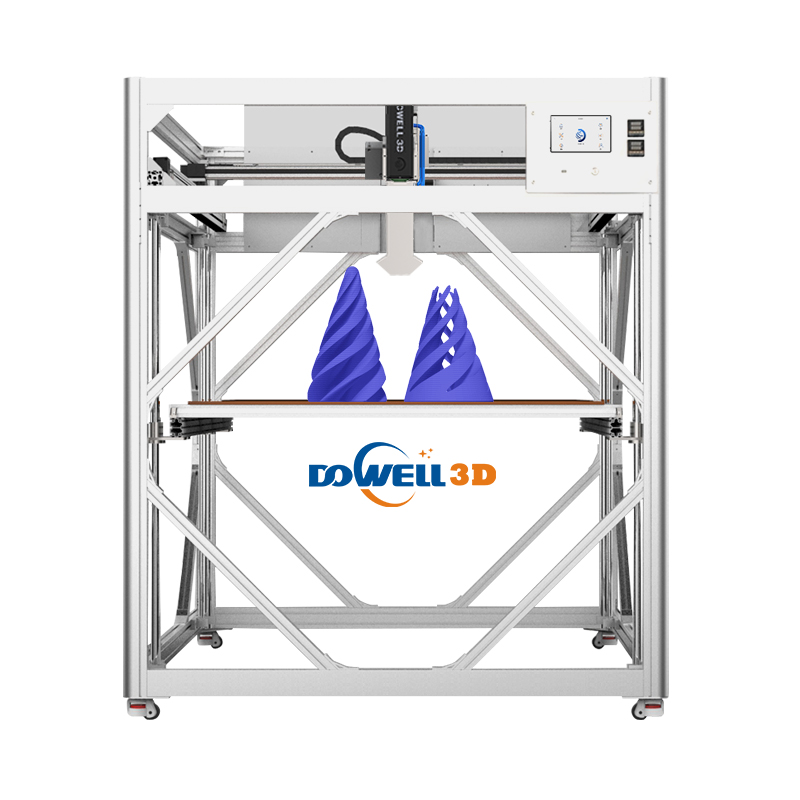

In the evolving world of 3D printing, Fused Granular Fabrication (FGF) pellet printing is emerging as a game-changing

technology that transcends traditional filament limitations. While FDM printers using filament have dominated the

consumer and prosumer markets, FGF pellet printers are unlocking unprecedented possibilities for large-scale,

cost-effective, and sustainable manufacturing. This technology's ability to process raw plastic pellets directly offers

significant advantages in material cost, printing speed, and scalability that are revolutionizing various industries.

Showcase the versatility of FGF printing beyond traditional manufacturing.

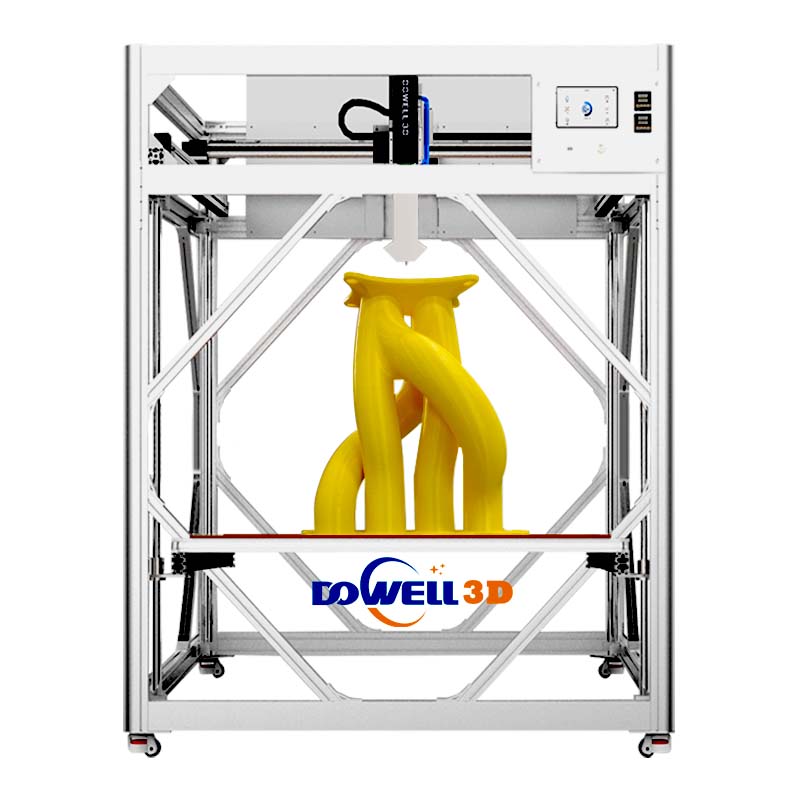

* Furniture and Interior Design

The furniture industry is experiencing a transformation through FGF pellet printing, enabling designers to create complex,

customized pieces that were previously impossible or prohibitively expensive with traditional manufacturing methods.

Large Build Volume: Create chairs, tables, and shelves as one continuous piece.

Material Economy: Pellets printing costs a fraction of filament, making large prints economically viable.

Design Freedom: Produce complex, organic geometries that are impossible with traditional woodworking or injection molding.

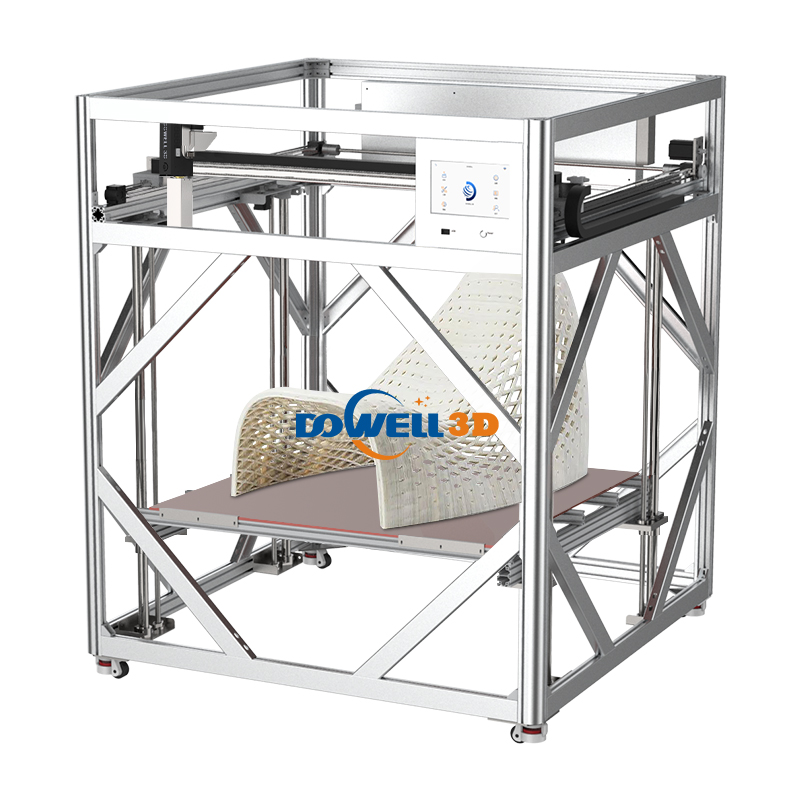

*Architectural Structures and Art Installations

From scale models to full-scale building components, the FGF 3d printing is reshaping architecture and art.

Architectural Components: Print large-scale building elements and structural components

Public Art Installations: Create massive, intricate art pieces for public spaces

Custom Facades: Produce unique architectural facades with complex patterns

Temporary Structures: Rapidly deploy temporary shelters and event structures

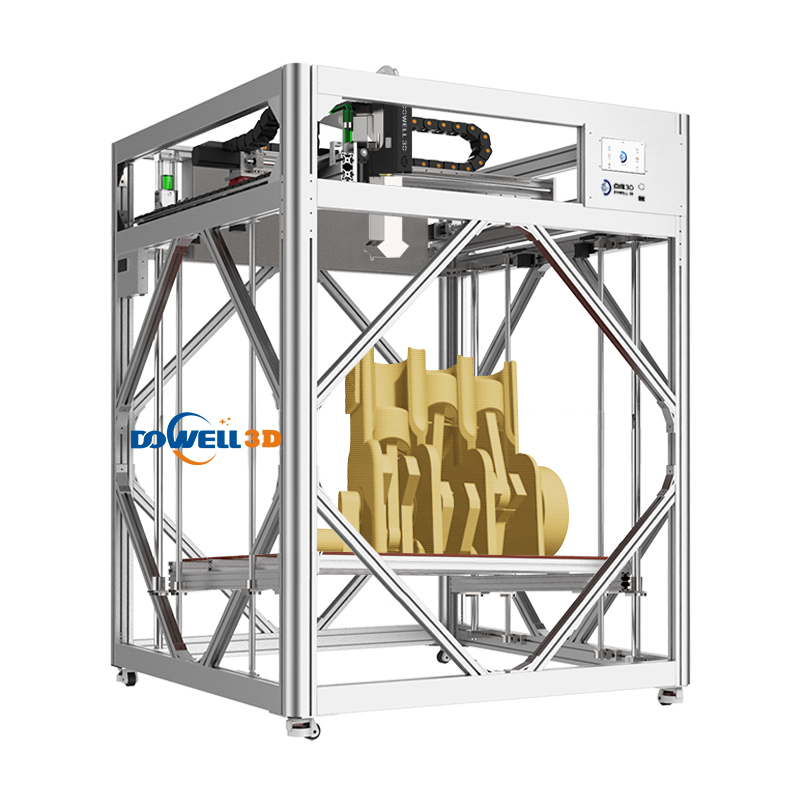

*Custom Tools and Molds

FGF pellet 3d printing is revolutionizing tooling and mold manufacturing, providing industries with rapid, cost-effective solutions for custom manufacturing needs.

Cost-Effective & Fast: Produce a custom jig or fixture for a specific task in hours for just a few dollars in material.

Custom Jigs and Fixtures: Create specialized tools for assembly lines

Injection Molds: Produce low-volume injection molds for prototyping

Composite Tooling: Manufacture tools for composite layup processes

Specialized Hand Tools: Design ergonomic tools for specific applications

In-House Production: Become self-sufficient and reduce lead times from external suppliers.

*Sustainable Projects and Circular Economy

FGF technology plays a crucial role in advancing sustainable manufacturing practices and supporting circular economy initiatives through its unique material capabilities.

Recycled Material Processing: Directly uses post-consumer and post-industrial plastic waste

Biodegradable Material Use: Process PLA and other biodegradable pellets

Waste Reduction: Minimize material waste through precise deposition and recycling capabilities

Energy Efficiency: Lower energy consumption compared to traditional 3d printing machines

Material Innovation: Support the development of sustainable material alternatives

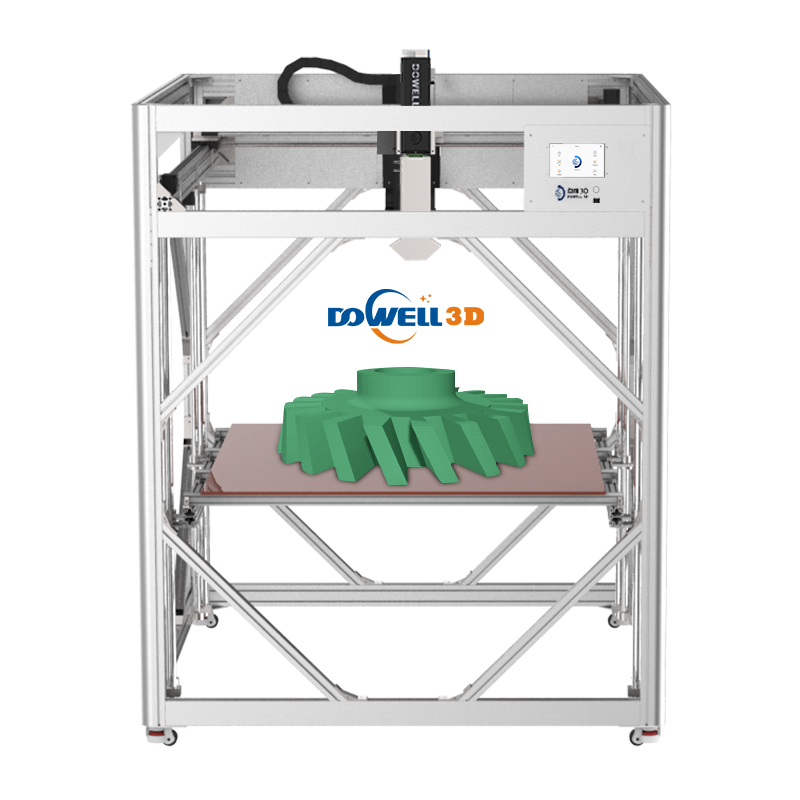

*Functional Prototypes with Engineering Materials

FGF 3d pellet printer enables rapid prototyping with engineering-grade materials, providing functional testing capabilities that closely mimic final production parts.

Wide Material Compatibility: Print directly from engineering-grade thermoplastics like PA (Nylon), PP (Polypropylene),

PETG, TPE, and fiber-filled composites, and other high-performance materials.

Durability: Produce strong, functional parts that can withstand real-world use and stress.

Full-Scale Production: Create end-use parts for machinery, automotive, or aerospace applications without the need for expensive tooling.

Explore DOWELL3D FGF Printer Series:https://www.dowell3dprinter.com/product-list/pellet-3d-printer

Contact us for a Custom Consultation:https://www.dowell3dprinter.com/contact