3D Printing in the Furniture Industry

In the ever-evolving field of furniture design and manufacturing, 3D printing has emerged as a disruptive

technology. The furniture industry is now shifting towards more customized, sustainable, and cost-effective

production methods. Unlike traditional furniture manufacturing methods, such as subtractive processes

like cutting, carving, or molding, 3D printed furniture is built layer by layer based on a digital 3D model,

using materials such as filaments, powders, or resins. This process offers greater design freedom, higher

levels of customization, and the ability to create complex shapes and intricate details that are difficult or

impossible to achieve with traditional methods.

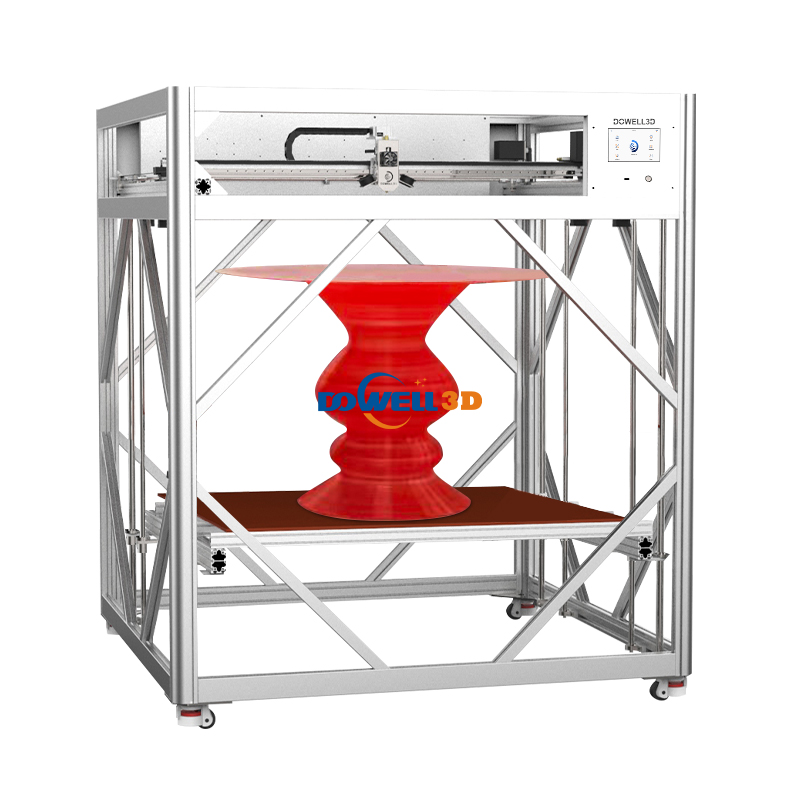

This video shows the printing process of a colorful chair using our DOWELL3D large-format industrial 3D printer.

If you are interested in this, please contact us.

One of the main advantages of 3D printed furniture is the ability to create highly customized and unique designs to

meet individual preferences or specific needs. Furthermore, 3D printing enables on-demand production, reducing

the need for large manufacturing facilities and inventory storage.

Why Filament-Based 3D Printing is Perfect for Furniture Manufacturing?

1. Customization and Personalization

The demand for personalized furniture is higher than ever, and traditional manufacturing methods often fall short

of providing the level of customization that modern consumers expect. With filament-based 3D printing, designers

and manufacturers can easily produce custom designs, allowing for unique shapes, sizes, and intricate details that

would be impossible to achieve with conventional methods. This allows customers to choose furniture that

perfectly fits their space, style, and functionality needs.

2. Cost-Effective Production

Traditional furniture production can be expensive, especially when it comes to prototyping and small batch runs.

Filament-based 3D printing reduces the need for costly molds, tooling, and manual labor, making it an affordable

option for producing both one-off pieces and small runs. Additionally, 3D printing minimizes material waste, which

further reduces costs and contributes to a more sustainable manufacturing process.

3. Speed and Efficiency

Time is money in the manufacturing world, and 3D printing can drastically reduce production time. Instead of

waiting for weeks or months to produce and assemble traditional furniture, manufacturers can quickly print

prototypes and even final products. This allows for faster product development cycles, which is crucial in the

competitive furniture industry.

4. Sustainability

Sustainability is a top priority for many companies and consumers today. By using filament-based 3D printing,

businesses can reduce their environmental footprint by minimizing material waste, energy consumption, and

transportation costs. Additionally, 3D printers are capable of using recycled filaments, further supporting eco-

friendly production practices.

Key Challenges and How DOWELL3D Overcomes Them

While 3D printing in the furniture industry offers numerous benefits, there are also some challenges that

manufacturers may face, including material limitations, post-processing requirements, and ensuring the

durability of printed furniture.

1. Material Selection

Filament-based 3D printing uses a variety of materials, each with its own properties. For furniture manufacturing,

durability and aesthetic appeal are key factors. Fortunately, DOWELL3D offers a wide range of high-quality filaments,

including PLA, ABS, PETG, and more, ensuring that manufacturers can select the best material for their specific

needs. Our filaments are known for their superior strength, flexibility, and finish, making them perfect for creating

furniture that lasts.

2. Post-Processing

Once a piece of furniture is printed, it often requires some post-processing, such as sanding, painting, or assembly.

While this can be time-consuming, DOWELL3D’s advanced printers produce smooth, high-quality prints that

minimize the need for extensive post-processing. Additionally, our 3D printers are equipped with features that

ensure consistency and precision, reducing the risk of defects.

3. Durability and Strength

One common concern with 3D-printed furniture is its durability compared to traditionally manufactured pieces.

However, with the right materials and printing techniques, 3D-printed furniture can be just as strong and long-

lasting as conventional options. DOWELL3D’s filament is engineered for strength and durability, ensuring that

your 3D-printed furniture is both functional and stylish.

Real-Life Examples of 3D Printed Furniture

To give you a better idea of how 3D printing can be applied to furniture manufacturing, here are a few examples of

furniture pieces printed using DOWELL3D machines and filament.

| The flower-inspired chair exemplifies how 3D printing can merge artistic design with functionality. | This 3D-printed coffee table features a unique design, showcasing the limitless creative possibilities of 3D printing. | This exquisite vase showcases the endless design possibilities offered by 3D printing technology. |

|  |  |

Conclusion

The use of filament-based 3D printing in the furniture industry is opening up exciting new possibilities for designers,

manufacturers, and consumers alike. With the ability to create custom, cost-effective, and sustainable furniture, 3D

printing is undoubtedly the future of furniture production. At DOWELL3D, we’re proud to be at the forefront of this

transformation, offering high-quality filaments and reliable 3D printers to help you bring your ideas to life.

Ready to start your journey into 3D printing? Choose DOWELL3D for all your 3D printing needs, and take advantage

of our years of experience, high-quality products, and dedicated customer support.