Large 3d Printer 600x600x600mm Auto Leveling Industrial 3d Printer With Metal Shell

- DOWELL3D

- China

- 10-16 days

- 1000 sets/month

600×600×600mm Large size Industrial FDM 3d printer with metal shell constant temperature chamber

*380℃ high-temp nozzle for enginneering-grade filaments

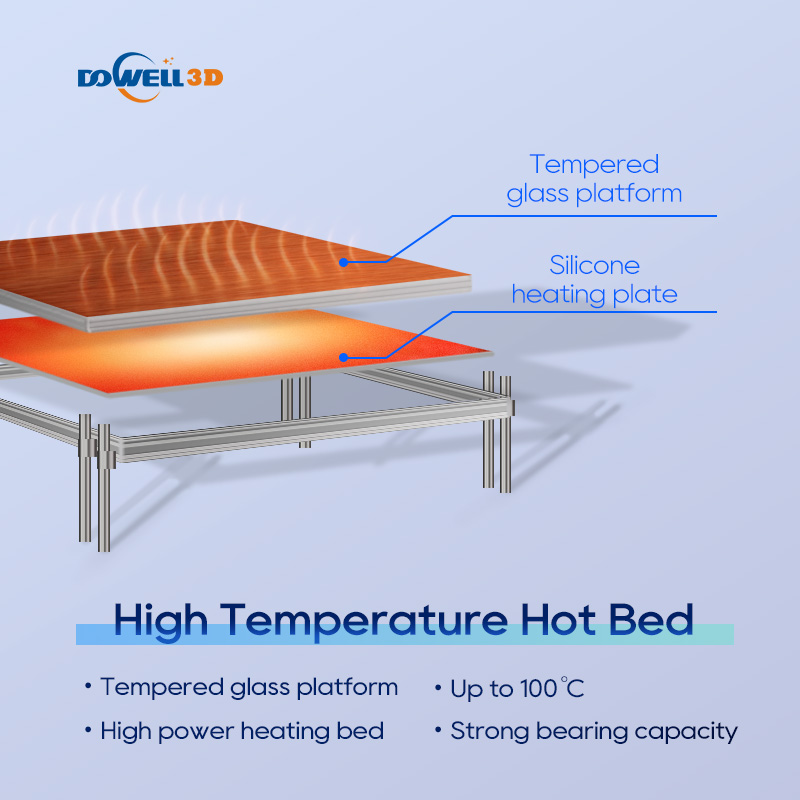

*6mm 100℃ high temperature glass platform

*60°C Constant Temperature Chamber

*Filament detection and power-off recovery functions

DH SERIES PRINTERS

The Dowell DH Series 3D Printer offers a large printing size of 1000*1000*1000mm, high-precision module

movements, and an enclosed metal shell for industrial-grade printing.

It features advanced temperature control, a durable 6mm glass heating bed, and supports multiple materials

like PLA, PETG, ABS, ASA, Nylon, CF, GF, WOOD, PVA, PMMA, and more. Equipped with a 7-inch full-color touch

screen, auto-leveling, filament detection, Camera and power-off recovery functions, it ensures intelligent and

stable performance.

The printer operates noiselessly, includes CE and FCC certifications ensuring compliance with EU and US standards.

| Model | DH600 | DH800 | DH1000 |

| Printing size | 600*600*600MM | 800*800*800MM | 1000*1000*1000MM |

| Nozzle diameter | 0.4/0.6/0.8 mm | ||

| Nozzle temperature | 0-380℃ | ||

| Bed temperature | 0-100℃ | ||

| Chamber constan temp | 0-60℃ | ||

| Location accuracy | 0.02 mm | ||

| Extrusion flow rate | 400g/hour | ||

| Print speed | 150-500mm/s | ||

| Operation interface | 7''full color touch screen | ||

| Operation firmware | Independent research and development | ||

| File format | STL/OBJ/GCODE/JPG | ||

| Filament available | 1.75mm PLA, PETG, ABS, ASA, PVA, WOOD, PLA+, CARBON FIBER, etc | ||

| Connection | SD Card / U Disk / WiFi | ||

| Input power | 110/220V | ||

Contact us for a detailed quote and customized solutions for our DH600/800/1000 models!

Features:

500mm/s fast printing speed for efficient mass production.

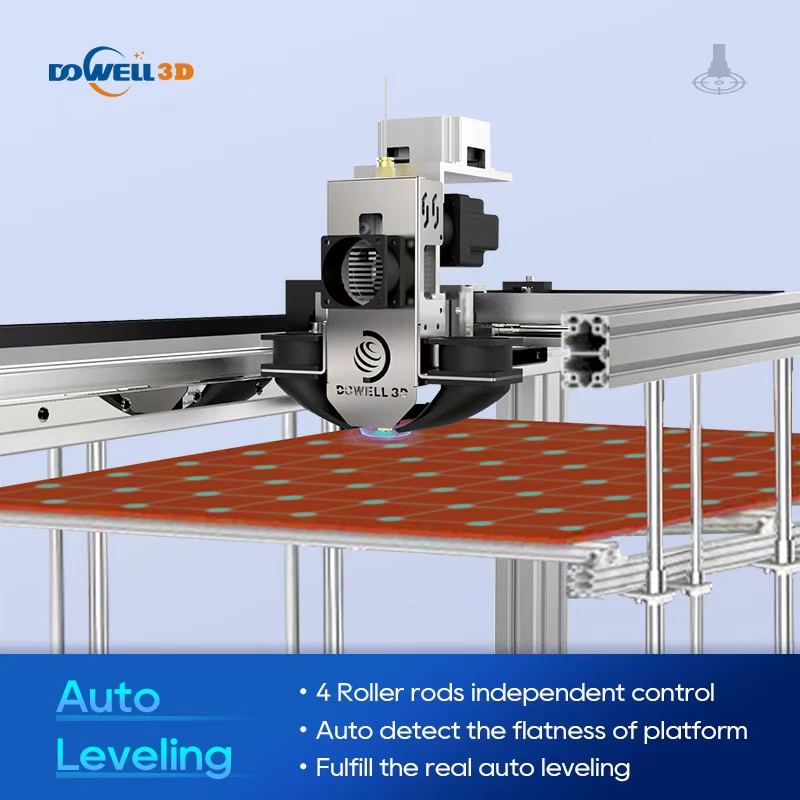

Automatic leveling eliminates operational barriers with one click.

Thickened metal shell and 60°C constant temperature chamber effectively prevent warping.

380°C high-temperature nozzle compatible with a wide range of engineering filaments.

Multi-door design for easy operation and maintenance.

Precision sliding module drive with 50dB low-noise operation.

Industrial heavy-duty wheels for both stability and flexibility.

100°C heated bed ensures secure model adhesion.

Power-off resume and 7-inch smart control screen for worry-free printing.

6mm 100°C high-temperature heated bed

The DH series is equipped with a silicone heating plate and a 6mm high-temperature glass heated bed, reaching

a maximum temperature of 100°C. This provides continuous and even heat to the bottom of the model, effectively

enhancing adhesion and ensuring that large or complex models remain firmly attached to the platform throughout

the printing process, ideal for printing with engineering-grade materials and avoiding warping issues.

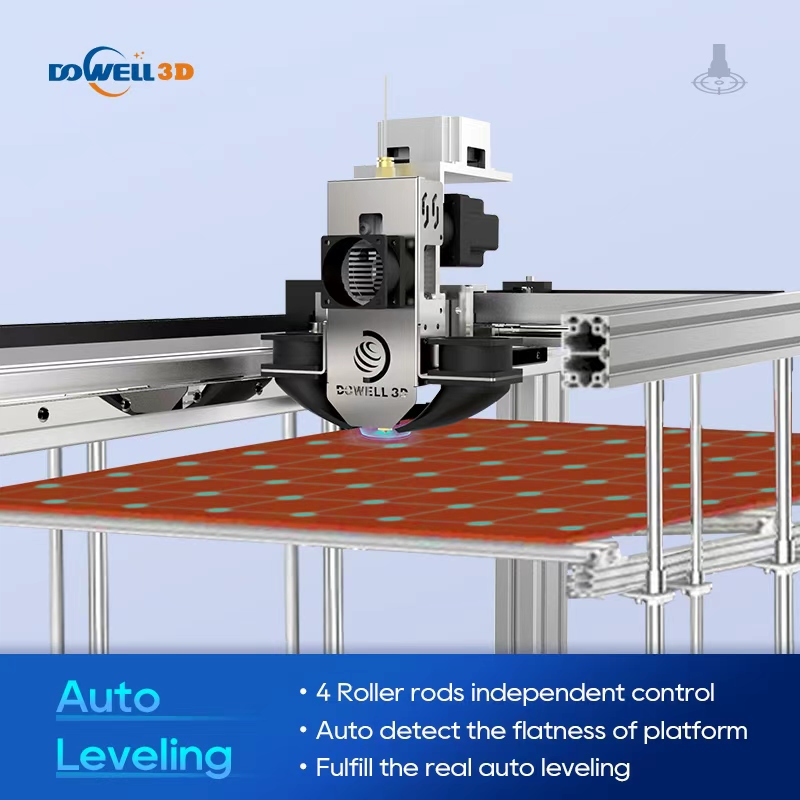

Auto leveling

Fully automatic bed leveling ensures perfect first-layer adhesion, eliminating the hassles and inaccuracies of

manual leveling. The machine is equipped with 4 Roller rods independent control, and high-precision sensors

automatically detect platform flatness, achieving true automatic leveling. This ensures a uniform, level first layer

every time you print, significantly improving print success rates, which is especially crucial for large-format printing.

500mm/s High printing speed

Based on Dowell's independently developed firmware, the DH series supports a wide range of printing speeds,

from 150 to 500 mm/s. While ensuring model accuracy, it can complete printing tasks several times faster than

ordinary printers, making it an ideal choice for industrial users and studios seeking efficiency.

380℃ High temperature nozzle

The DH series uses a high-performance hot end with a nozzle temperature of up to 380°C. This temperature range

enables stable, fast, and smooth printing of engineering and composite filaments that require high-temperature

melting, such as ABS, ASA, PETG, Nylon, WOOD, PVA, PMMA and Carbon fiber reinforced filaments, fully unleashing

the potential of the filaments.

Multi-door structure easy to operate

The DH series features a user-friendly front door and top cover design. Unlike closed printer, the multi-door

opening structure allows users to easily open the front door or top cover, providing unobstructed access to the

entire build platform and print head. This greatly facilitates model loading and unloading, filaments replacement,

and internal maintenance, enhancing the user experience.

Power-off Resume:

The device features a power-off memory function.

If a power outage occurs during printing, the system will automatically notify you and resume printing from the

point where it was interrupted upon restoration, preserving valuable time and filaments and preventing wasted work.

The thickened metal shell not only provides industrial-grade rugged protection, but also forms an enclosed

constant-temperature printing chamber that can be heated and stabilized at 60°C, significantly reducing model

deformation during printing and fundamentally preventing warping and cracking caused by cold shrinkage of

materials such as ABS and carbon fiber.

Sliding Module Drive & Noiseless Drive

Utilizing high-precision linear guides and CNC-grade sliding modules, this system delivers improved straightness,

greater load capacity, faster speeds, and higher precision. This ensures the stability and durability of moving parts,

resulting in a smooth, fast, and quiet (approximately 50 decibels) printing experience. No more noise interference.

Official Notice:

Dear Valued Customers,

This is the only official store of Luoyang Dowell 3D Electronic Technology Co., Ltd.

We are the sole manufacturer and exporter of Dowell3D 3D printers and related products.

Please note:

We have not authorized any third-party websites or suppliers to distribute or resell our products.

Products sold under the "Dowell3D" brand on other platforms or websites are counterfeit and unauthorized.

They lack genuine quality, technical support, and after-sales service. Please exercise caution and discretion

when purchasing.

Choose us without hesitation; it will be the best decision you make.

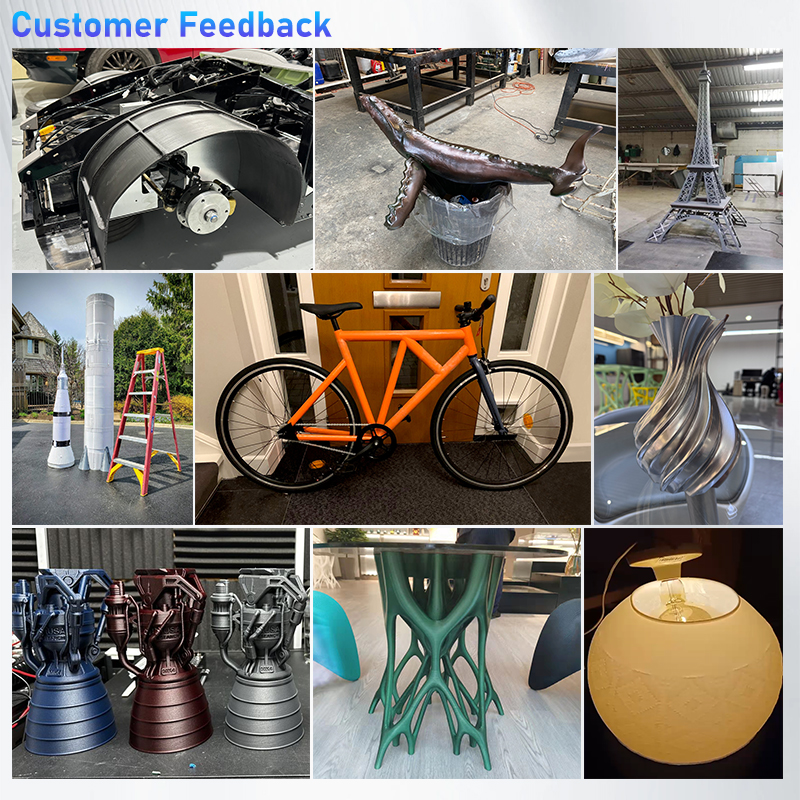

Customer's Printing Cases

Why Choose DOWELL 3D ?

Factory Direct Sales:

We are one of the largest 3D printer manufacturers in the global market, offering high-quality products at

competitive prices.

Professional Customer Service:

Our dedicated customer service team is always ready to assist you, answering queries and providing support

whenever needed. All inquiries will be responded to within 24 hours.

Continuous Innovation:

We are committed to continual technological advancements and service enhancements to elevate your

purchasing and product experience.

FAQ

1-Are you a factory?

Yes, we are a directly manufacturer focus on developing and produce large industrial-grade 3D printers.

2-Payment method?

T/T (Bank transfer), PayPal, Western Union, Credit card, WeChat Pay, Ali Pay, T/T

3-Shipping method ?

Sea freight, Air freight, DHL. FedEx, UPS

4-What's your lead time?

We accept EXW, FOB, CIF, DDP, etc terms.

If the product you order is our standard model, lead time is around16 days; or else lead time is negotiable.

5-How do you guarantee the quality of the printer?

We conduct 100% testing before shipment. We provide test photos and videos before shipment.

We guarantee that our 3D printers will be free of any quality issues before shipment. Once confirmed,

we will arrange shipment