Pellet 3D Printer Advantages And its Applications

The world of 3D printing has evolved tremendously over the past decade, with various technologies

emerging to meet different needs. One of the most exciting and innovative developments in the field

is Pellet 3D Printing, also known as FGF (Fused Granular Filament) Printing. Unlike traditional

filament-based 3D printing, which uses spooled filament, Pellet 3D printers utilize small pellets of

filament, which offer significant benefits in terms of cost, material diversity, and printing efficiency.

If you're looking for ways to take your 3D printing projects to the next level, here’s why Pellet 3D

Printers might be the game-changer you need.

What is a Pellet 3D Printer?

Simply put, a pellet 3D printer is an innovative machine that harnesses the technology of fused granular

fabrication (FGF) to print objects. Instead of the usual filament strands catered for by the majority of 3D

printers, pellet 3D printers utilize raw, discrete plastic pellets to propel novelistic prototypes, blazing a

trail in print-style sophistries often conveyed in sizeable capacities.

How does Pellet 3D Printing work?

Quite intriguingly, the operational normality behind pellet 3D printing squarely resonates with the popular

fused deposition modeling (FDM). The only significant difference lies in the method of material input and

the specially designed extruder used to process plastic pellets instead of FDM filament. The technology

uses an extruder that feeds pellets into a heated nozzle, where they are melted and deposited layer by layer

to form an innovative 3D object. This approach offers significant advantages, especially for industrial and

high-volume printing needs.

Key Advantages of Pellet 3D Printers

1. Lower Material Costs

One of the most significant advantages of Pellet 3D printing is cost efficiency. Traditional filament, especially

in large quantities, can be expensive. In contrast, pellets are much cheaper to produce, and they can be

purchased in bulk, offering a much more affordable way to print large objects. This makes Pellet 3D printing

ideal for businesses that need to print large parts at a lower cost per unit.

2. Faster Printing Speeds

Pellet 3D printers can print significantly faster than traditional filament-based printers. Since pellets have

a higher density and can be processed more quickly than filament, the extruder can melt and extrude

material at higher speeds, leading to faster print times. This is a crucial benefit for businesses or industries

requiring quick turnaround times, whether for prototypes, tools, or production runs.

3. Wider Material Variety

With Pellet 3D printing, the range of materials you can use is broader than that of traditional filament-

based 3D printers can handle. In addition to standard filaments like PLA, ABS, and PETG, Pellet 3D printers

can support a wide variety of specialty filaments, including PP, PP+Carbon fiber, TPE, and flexible materials.

This wide range of material options opens up possibilities for a wider array of applications, from prototypes

to fully functional industrial parts.

4. Better Sustainability

Pellet 3D printing is often considered a more sustainable option for high-volume production. Many Pellet

3D printers allow for the recycling of waste material or the reuse of unused pellets. This reduces material

waste, contributes to environmental sustainability, and offers a more eco-friendly way to print in bulk.

The ability to use recycled filaments or environmentally friendly materials also allows companies to meet

sustainability goals.

Applications of Pellet 3D Printing

1. Large-Format Industrial Parts: Due to high throughput, it is ideal for producing large, complex objects

like furniture, art installations, and construction components.

2. Prototyping and Product Development: Pellet 3D printers are ideal for rapid prototyping and product

development. The ability to print quickly and affordably means that designers and engineers can iterate on

their designs faster, testing and refining prototypes before committing to final production.

3. Aerospace and Aviation: Aerospace companies benefit from Pellet 3D printing because of the strength and

lightweight properties of materials like carbon fiber-filled filaments. This technology can be used to produce

custom parts, tools, and functional components that meet the demanding requirements of the aerospace industry.

4. Medical and Healthcare Applications: In the medical field, Pellet 3D printing is used to create custom implants,

prosthetics, and orthotic devices. The ability to use a wide range of materials with specific properties, like flexibility

or strength, makes Pellet 3D printing an ideal choice for creating personalized medical devices.

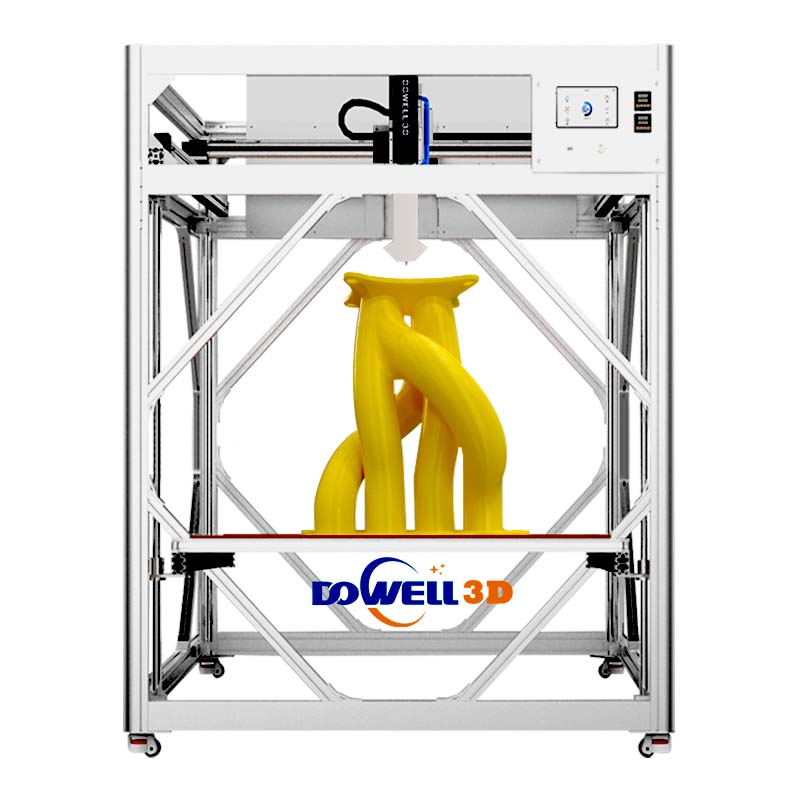

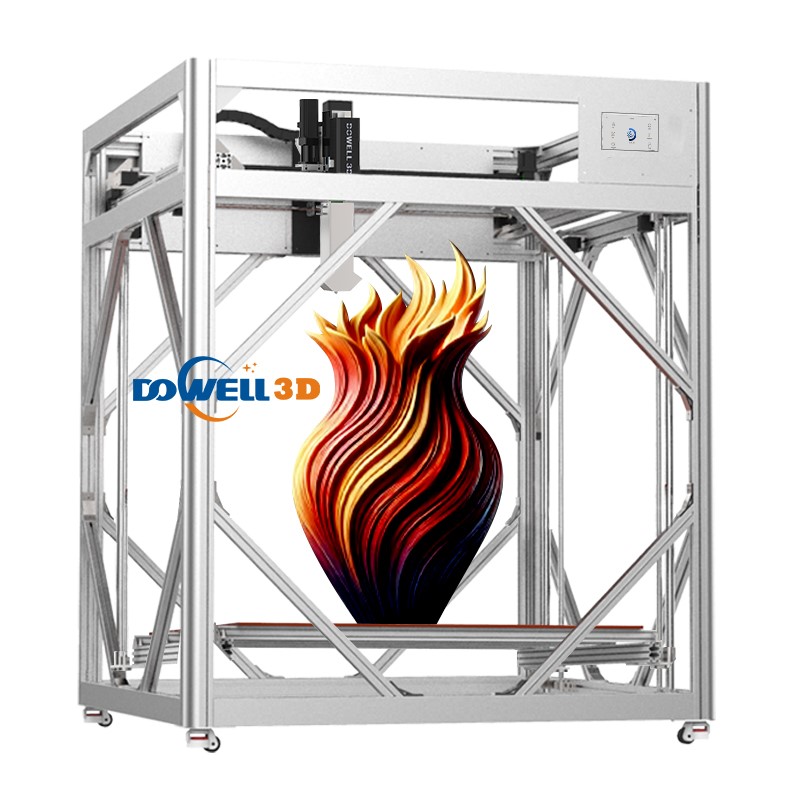

Dowell3D Pellet 3d printer

With 11 years of manufacturing and export experience, DOWELL3D proudly offers cutting-edge FGF pellet

3D printers. Our printers are designed with precision, durability, and ease of use in mind, delivering unparalleled

performance in the field of FGF 3D printing. We are more than just a printer supplier; we are your partner in your

3D printing journey, providing high-quality filaments and comprehensive customer support.